During the analysis process, the Lin Engineering team selected which components were critical to most design needs to make selection easy, quick, and repeatable in a production setting — benefitting the manufacturer and customer.

Rapid prototyping is often thought to be about building plastic parts for use inside your system, or perhaps as an enclosure or mounting component. But there are other ways to use rapid prototyping to advance your design engineering capabilities — in this case, linear motion design.

We don’t have to cover the many benefits of using rapid prototyped parts during the earliest stages of product design. Speed to market seems like enough. But, in the case of linear motion component production, having precisely the right part for your application is even more critical. We’re talking about saving money by eliminating over-design, but we’re also talking about footprint, specifications, and long life.

To explore this concept of rapid prototyping for linear motion devices, we’ll cover two things: what modular component designs can do for fast customization, and how an online configurator can focus your idea quickly before making a final selection. Both of these explorations will reduce time to market and minimize cost escalations from unnecessary customization.

Whenever a customer wanted something different than what was offered in a general catalog — often to make them more competitive in cost or capabilities — they had to go through each specification, select what they want, and then wait between six and eight weeks to receive a prototype linear motion device. But they often needed the prototype much faster than that so that they could evaluate their choice and make additional adjustments if needed. There was no off-the-shelf answer. This method often came at a high cost.

On a manufacturer’s side, the questions were how to shrink the lead-time without having to stock a lot of inventory (with incremental adjustments to standard products). They also had to account for how to provide customization—even in small increments—to help satisfy what was determined to be between 50 and 70% of the customers who needed a custom prototype. Such a product line would have to be highly flexible and quickly delivered. These same prototypes would then have to be able to go into production with no lag in delivery.

Some manufacturers are looking at ways to get the most flexibility out of their linear motion products by stocking components properly and in such a way as to make as many selections as possible within the shortest amount of time.

Modular product structures are not new, but when you’re talking about a complex product like a linear drive, there are many components to consider. The more components, the more complex a design can get, and the more difficult it is to discuss and select the right product for a particular application. This situation is why using a catalog to make a selection can get complicated. If an engineer is looking at the multitude of specifications without a full understanding of which ones are critical and which are not, the selection process becomes overwhelming. At this point, many engineers default to over-specifying parts, driving up costs, and having to adjust product footprints.

In the production of linear drives, the essential components include the motor, the lead screws appropriate to each motor (to eliminate mistakes in configurations that won’t work), nut sizes, and finishes. With a variety of each of these components, narrowing down what will work together and what an engineer might need for a specific application could become a nightmare. Nonetheless, by understanding common requirements like required force, speed, available power, and current draw, they could help to make the right selection of components.

Engineers are doing more and more of their selections online, which means that companies must be more accessible. Most companies have uploaded their catalogs. However, with only an online catalog, engineers often had to talk with the manufacturer once they were close to making a decision. This usually means speaking with a sales person who would steer them toward a product that might not suit their application. Thus, customization can come with a high price tag.

The online catalog approach ignores the fact that many engineers want to play around with the parts for a while before asking an expert at all. An online configurator removes the sales pressure and allows the engineer to better understand what they need as a final product.

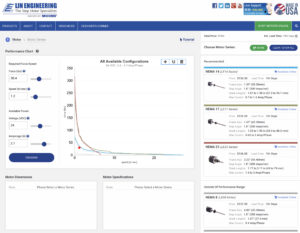

Lin Engineering offers the Rapid Prototype Configurator to address these needs of the engineer. Using the configurator, an engineer doesn’t have to talk with a salesperson until they have nailed down their needs. The configurator operates with a 10% safety buffer on product selection so prototyped products can be easily configured, selected, delivered, and installed without worrying that the component might not work properly.

Engineers can play with the prototype, consider their specific application needs, and continue to hone their design — even if they feel they need more customization. The prototype parts, configured from hundreds of combinations of products, are deliverable in roughly three weeks. And for designs that require faster deliveries, a one-week option is available with minimal rush fees.

Ultimately, what a manufacturer needs is to provide services to engineers focused on their needs and not just the products the manufacturer wishes to sell. If a manufacturer can help an engineer get close to their product needs quickly, without sales pressure; allow them to incorporate those changes right away, to evaluate their specific requirements; and do these things using modular designs, which minimizes potential flaws; then products can be designed and delivered efficiently.

Lin Engineering

www.linengineering.com

Filed Under: LINEAR MOTION