By Kevin Kakascik, AutomationDirect

So you have a big home project planned for this weekend, like building a deck. Earlier in the week, you stopped at the hardware store and picked up all the lumber and some necessary tools not already in your kit. Now it’s Saturday and you wake up early to get a jump on things before it gets too hot outside. The weather is perfect as you set out all the materials — only to spot you are missing deck screws. Sound familiar?

You hurriedly drive to the hardware store, buy the deck screws, then return home and resume working. Another hour into your project, after cutting the lumber, you begin framing, only to realize you are missing joist hangers, requiring another frustrating round trip to the hardware store. How could you forget these small yet crucial items for your project? It’s simple — because they are small, they often times take a lower priority to the larger items.

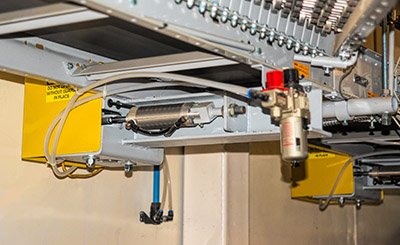

Figure 1. It is easy to focus on larger items for a pneumatic installation, and overlook smaller but crucial components. All figures courtesy of AutomationDirect.

This syndrome of overlooking details is also quite common for industrial pneumatics projects. Designers plan the system, determine pressure and flow requirements, select control components, and focus on larger items like cylinders, Figure 1. Yet often times, some smaller but crucial components are missed. While these parts may be available at a local distributor, many pneumatics components aren’t for sale at the hardware store down the street.

Having all the parts on hand can make the difference between getting a project up and running quickly or delaying the work and incurring additional costs. Let’s examine several pneumatic components that are oftentimes overlooked when creating a pneumatic system bill of materials (BOM).

Tubing

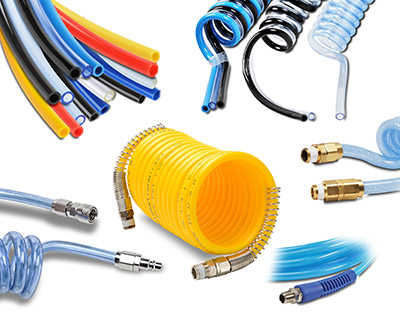

Flexible and durable tubing connects devices together by transporting compressed gas, usually air (but sometimes nitrogen), Figure 2. Most pneumatic systems use some amount of flexible tubing unless they are entirely hard-piped.

Figure 2. Pneumatic tubing is available in many sizes and colors.

Some designs may use just one size and color of tubing, making it easy to stock the right material. But many installations need multiple tubing sizes, and oftentimes it is helpful to use various colors to identify functionality. Special tubing for extreme temperatures or added flexibility may be needed. For these and other cases, getting the right materials on hand is more complicated.

Usually, the tubing is remembered with the initial material order because designers plan for what is needed. However, an installation often runs short because the necessary lengths were not calculated properly to account for twists, turns, and tough-to-reach locations.

When an installation runs short on tubing, a local supplier may have enough of the right size and color in stock to match the already completed work — but this is a gamble compared to ordering enough upfront. When it comes to tubing, it pays to standardize as much as possible, over-order to some extent, and work with a supplier offering a comprehensive product selection.

Figure 3. Even one missing pneumatic fitting can prevent project completion.

Fittings

Fittings are used to connect tubing to devices or other sections of tubing, and they are typically threaded on one end and have push-to-connect or barb connections on the other, Figure 3. Because the fittings must accommodate various tubing and device sizes, many styles may be needed.

Careful planning is required to ensure the correct sizes are ordered. Outside diameter of the tubing determines push to connect size, while inside diameter determines the type barb style fitting. Threaded size is very important because there are different types:

• National pipe thread (NPT), tapered

• British standard pipe thread (BSPT), tapered R-thread

• British standard parallel pipe (BSPP), straight G-thread

• Metric versus United States (or British) sizes

Beyond the size, each fitting must be selected with the right materials of construction based on the environment and operating pressure. Stainless or thermoplastic are options for push to connect fittings. Barb style fittings are usually brass.

A missing or incorrectly sized or specified fitting can add days to a project schedule.

Manifolds

Pneumatic manifolds save space by distributing compressed gas to multiple devices — analogous to how power distribution blocks can provide an electrical supply to multiple loads. Manifolds make the most sense when there are many connections of a similar size needed in a location, all with compatible pressure and flow requirements.

While manifolds are not required and may not even be recommended for very small systems, they are low cost and provide a compact installation. Manifolds make for a neater and cleaner installation, and help avoid a spaghetti-like installation mess, which is hard to troubleshoot and maintain.

As with other fittings, manifolds come in many different materials such as aluminum, nylon, polypropylene, and stainless steel. Various port sizes, quantities, and arrangements are also available. Planning is necessary to ensure there are enough ports, and also to provide plugs for unused ports. If an installation comes up short on manifolds, there may be a workaround using other fittings, but it won’t look as elegant.

Manual shutoff and isolation/lockout valves

Figure 4. Manual shutoff and isolation/lockout valves are crucial for any pneumatic system.

Manual shutoff valves can be used to isolate downstream devices from upstream air pressure, analogous to how an electrical disconnect switch de-energizes downstream loads, Figure 4. They can also be locked-out in the safe position just like an electrical disconnect. Shutoff valves can be used to isolate a system that won’t be used for a while, and they can also be arranged so users can de-pressurize an isolated system.

Manual isolation/lockout valves operate similarly to basic manual valves except they bleed off downstream air pressure when closed. These valves are the pneumatic portion of an emergency stop circuit and can operate quickly. Per OSHA standard 1910.147, for all automated machinery the operating personnel must be capable of quickly relieving of all “hazardous energy.” Isolation/lockout valves are OSHA-approved for this purpose.

Valves are necessary to properly supply, isolate, and de-pressurize pneumatic systems. They must be arranged so equipment can be locked out by maintenance personnel, who can then safely perform work without fear of equipment moving pneumatically. Each project needs all the valves on-hand and ready for installation so the equipment can be operated safely.

Automatic soft start valves

An automatic soft start valve is a three-way, two-position solenoid device that is installed upstream of all moving pneumatic equipment. When the machine requires air pressure, the controls energize the soft start valve, which has an adjustable ramp-up time to apply pressure gradually. This increases the life of pneumatic equipment and prevents any sudden mechanical movement that can cause noise, breakage, or injury.

When de-energized, soft-start valves also act as a relief valve to quickly relieve downstream air pressure. Soft-start valves are usually installed in series with a manual shutoff valve, but they don’t satisfy the requirement for a manual shut-off valve or isolation valve.

Only one soft start valve is typically needed per an equipment area, and they are not required but are a good design practice. The system can be plumbed to run without one, so it is easy to forget this device during initial designs.

Exhaust mufflers

Exhaust mufflers are some of the smallest, simplest, and least expensive pneumatic components. They screw directly into the exhaust port of control valves, shutoff valves, and isolation valves, reducing the noise created by the device exhausting air to atmosphere.

Technically, exhaust mufflers are not needed for a system to function. However, they provide a more comfortable and safer occupational environment, and OSHA standard 1926.52 requires employers to protect their employees from continuous noises exceeding specified decibel levels for varying amounts of time.

Specialty fittings

Figure 5. Specialty pneumatic fittings encompass many types of components.

The term “specialty fitting” or “special purpose fitting” is a catch-all for any functions that may be less commonly used for an application, Figure 5. Some examples are:

• Small flow control restrictor valves, used to lower actuator speeds

• Check valves to allow airflow in only one direction

• Shuttle valves which shift to route the higher pressure from one of two inputs to the output

• Bleeder valves with manual pushbuttons to bleed pressure trapped in part of a system

These items are special in the sense that a designer may not typically use them, which is a good reason why they might be overlooked during design. However, many of these items can be difficult to source locally and should be carefully ordered in advance.

Sweat the small stuff

Projects of all types benefit from careful planning. For pneumatics projects, there are many components that may be overlooked or underestimated. These sometimes-forgotten components don’t always cost a lot, but they may not be readily available from the hardware store around the corner. Obtaining sufficient quantities of the right parts in advance helps keep installation efforts on time, within budget, and safe.

Filed Under: Pneumatic equipment + components, FLUID POWER