A new motion control project has landed on your desk. You know that it makes sense to connect automation components together using a network, but with so many competing networks to choose from, which one is the most appropriate choice?

If you design machines that include a few independent motors, you most likely do not need to network the motor controllers or drives. Software can simply command the independent drives to move a set distance or number of degrees. But when products such as pick-and-place machines, semiconductor-processing apparatus and other precision equipment require multiple drive “cooperation” with motion coordination, networked control becomes a must.

Network characteristics

First, look at some distinguishing characteristics of the available networks. They can be grouped into the three main categories as shown to the right.

Broadly speaking, general-purpose field busses send messages when they are needed, which makes best use of the available network bandwidth. Motion busses, on the other hand, constrain network traffic according to a repeating timetable; which ensures that control actions are timed deterministically.

Motion busses reconstruct the clock from a central controller at each node. The reconstruction has two principal advantages: It allows the time at which an input changes to be measured to an accuracy of less than 1 ms or the time at which an output is set to be accurately controlled. And, it allows both position measurements to take place and command values to take effect with predictable timing, capabilities that are essential for the closure of loops through the network.

Some networks, such as EtherCAT and SynqNet, have I/O that handles these time and position related functions in logic gates (hardware-to-the-pin) at the drives to achieve the required accuracy.

In order for motion busses to offer high cyclic update rates, the packet usage or packet structure have been adapted from classic Ethernet usage to increase the network’s data efficiency. The rates that are actually achievable depend on network loading and controller processing capability; communicating with 100 single axis nodes at 1 kHz or servicing 10 single axis nodes at 10 kHz are indicative of busses designed specifically to handle motion. Note however that although the cyclic rate is the industry figure of merit, control latency is more important for achieving tight control. Published data are scarce so be sure to ask your supplier — especially if you plan to close loops via the network.

Hybrid networks aspire to combine the flexibility of the general-purpose network with predictable timing for motion control. They support a mixture of scheduled and unscheduled traffic along with distributed clocks. They are capable of sending command values to some number of axes at low cyclic rate, such as =1 kHz. Loop closure through the network is not generally feasible with hybrid networks but nevertheless they have an appeal — particularly where the network in question is already in use at plant level.

The following chart shows where several well-known networks would fit in this view.

The table includes those networks known to have significant installed bases, major sponsors, and which have been adequately described in publicly available literature.

The precise assignment of some of the networks to particular categories is necessarily subjective: for example, the EtherCAT implementations described to date all emit the packet from the master under software control and the timing uncertainty this causes is in contrast with no-compromise motion busses.

Only networks based on 100-base-T Ethernet technology have been included as this is the

direction that the industry is taking. It remains to be seen whether Gigabit Ethernet will reach right down to the devices themselves or whether its use will be confined to upper tiers of the network.

Despite sharing the same underlying physical layer, these networks have diverse topologies and characteristics.

Be sure to consider the cost and configuration of network hardware. Standard switches are inexpensive and simple to install. Managed switches are more expensive and can be difficult to set-up. Switches with IEEE1588 are somewhat exotic, for example an 8-port Cisco Industrial Ethernet 3000 switch retails for $1400. Hubs are obsolete and consequently suppliers must integrate this function into their nodes. Line and ring operation dispense with the need for switches. Some networks offer tiered topologies, Table 1 concerns only how devices themselves are attached. All of these networks claim some ability to attach nodes while the network is fully operational.

Fault-tolerant operation is a useful feature that, in the event of cable breakage or node failure, allows a machine to be brought to a safe state before cable repair or device substitution can be made. To be of practical use, a fault-tolerant ring in a motion network requires not only an alternative path by which to send and receive packets but also a means to preserve the operation of the distributed clocks at each node so as to ensure no disruption to motion-related actions, in this respect SynqNet is unique.

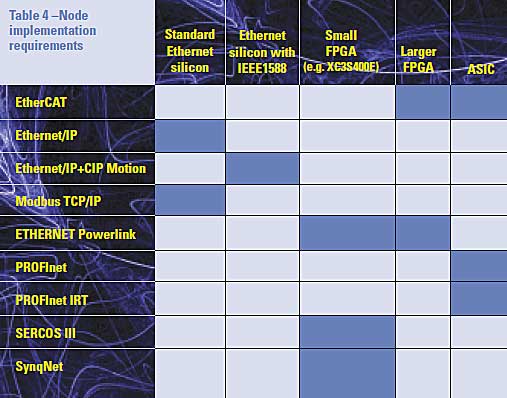

Lastly, it is worth looking at what it takes to implement the network at a node.

The node implementation is important because it affects both price and availability. Field busses that rely on ASICs have a dismal history of sporadic component shortages and expensive silicon. An advantage of using field programmable gate arrays (FPGAs) is that new, revised or corrected network functions can be added to existing product. At least one network (SynqNet) allows the node FPGAs to be updated through the network itself.

The selection process

A good place to start the network selection process is to determine whether the application really needs a network with specific motion control capabilities. For example, consider a cut-to-length machine: a servo motor advances a precise length of the work-piece and a second servo motor moves the cutter. The motion, typical of many applications, is sometimes termed indexing. The motion axes do not interact closely in this example, and indeed, only one axis is in motion at a time. It makes sense to delegate the position loop closure and profile generation to the servo drives themselves. The machine as a whole can be sequenced through the network from a PC or a PLC, or alternatively the drives can be responsible for their own sequencing.

There are no special requirements on the network in respect of timing, latency, throughput, simultaneity or determinism. In such cases a ‘vanilla’ Ethernet-based network such as Modbus TCP/IP should suffice and, with many drives having an Ethernet port included as standard, may be the most economical choice.

Now let’s consider more complex machines, say a pick-and-place machine for placing chocolates in trays or a continuous-feed printing machine. Such machines can have high axis counts (more than 20) and hundreds of I/O points located in dozens of I/O out-stations or on the servo drives. A network with specific motion control capabilities may not be essential: some level of inter-axis linkage can be implemented using master encoder inputs on the drives, for example to implement overall feed-rate control. The X-Y motion of the pick-and-place machine may be adequately fulfilled by activating simultaneous but independent motions on the X and Y axes.

However consider the advantages of using a network to carry the position information: inter-axis linkages can be performed using the network, removing the need to hard-wire any motion function and all motion will be executed with deterministic timing. Right, so having established that networked motion control would be at least advantageous, which bus would be appropriate?

The first question to answer is whether the machine is mainly a general automation application (solenoids, limit switches, indicator panels, HMI screens) with a need for some coordinated motion. If it is in this category then it is possible to automate the whole machine on a single hybrid network, without recourse to a motion bus provided that network has sufficient bandwidth and some capability for serving position targets to the drives on a cyclic basis. Networks that meet these criteria include Profinet IRT, which enforces prioritization of certain packets and has a distributed clock scheme, or Ethernet/IP, which uses IEEE-1588 to reconstruct clocks.

Hybrid networks run out of steam when the axis count is high (limited by network data efficiency); when motion-related I/O is required for measurement, inspection or alignment; or when multiple axes are to be coupled in software; or when co-ordinate transformation takes place. They are also unsuited to applications where the position loop will be closed through the network. In such cases a bus specific to motion is required.

As a third application example, consider a six-axis welding robot. These machines tend to use a dedicated motion controller to implement the co-ordinate transformations. Closure of the position or velocity loop at the drive is problematic because the inertia varies with the robot geometry, therefore the drives are operated in torque mode and other loops are closed through the network. For such applications a motion bus is essential.

In some cases it may be attractive to use a motion bus for the drives and another, more general-purpose network, for the I/O.So far we have considered technical aspects but there are other factors that should influence selection of the motion network.

For example what about product support? Is the entire system to be sourced from one supplier — in effect purchasing the motion system as a component? If it is, then it might be best to delegate the choice of network, along with the responsibility for getting it working, to that supplier. If network devices from several vendors will be combined on the same network then a realistic strategy must be devised to ensure their interoperability. Do not assume that because devices have been designed to conform to a published standard that they will work together out of the box. Finally there is the question of whether appropriate drives of the required types (servo, stepper, and inverter) are supported in the right power ratings. Some networks also offer multi-axis drives.

Today the machinery manufacturer is in the fortunate position of having many choices of 100 Mbit networks to serve motion control requirements. Each network has been conceived for a particular class of applications and it should be possible to make the right selection by identifying the motion control characteristics of the machine and matching them with those of the motion network.

Danaher Motion

www.danahermotion.com

::Design World::

As senior hardware design engineer for Danaher Motion Performance Controls, Robert Pearce designs PC-based motion controllers, servo drives and I/O devices for the motion control network SynqNet®.

With more than 35 years of motion control network design experience, Robert has designed over 70% of the servo drives and I/O devices used in the SynqNet network, and is named as one of the inventors on US patents 7,143,301 and 7,024,257 which relate to SynqNet technology. Earlier product designs included products for the CANopen network, as Robert served as chairman of CANopen SIG DS302 for several years. Since 2001, Robert has designed for the SynqNet network, and is currently focused on fault-tolerant positioning schemes for PC-based motion controllers and servo drives.

Robert holds a B.S. in Engineering from University of Exeter, and has participated in postgraduate work in vector control of induction motors for traction applications at the University of Bristol.

Filed Under: CONNECTIVITY • fieldbuses • networks

Tell Us What You Think!