A new line of side-loading case packers exceeds current green manufacturing end user trends, featuring servo control to increase speed and reduce energy costs within a compact footprint.

Brenton Engineering, a provider of packaging and palletizing equipment located in Alexandria, Minn., spent months consulting with customers and vendors before designing the next generation of its popular BrentonPro Series of case packer machines.

“We asked our customers how we could improve the machine. The feedback was to make it a faster and simpler all-servo machine,” said Mike Grinager, VP of Technology for Brenton Engineering. “With the new design we did everything we could to reduce the complexity of the machine. We took out the pneumatics, which was the most expensive aspect of the machine, and our engineers removed more than 200 moving parts, reducing costs by one-third. Plus, the integrated servo motors and drives that we now use require less space than even the smallest motors we used previously,” said Grinager.

As a result, the company’s BrentonPro Mach-2 case packer is an all-servo-driven, side-load case packer featuring an IndraDrive Mi integrated motor/drive platform with SERCOS distributed I/O, an IndraMotion MLC motion logic controller and the IndraControl VEP40 human machine interface all from Bosch Rexroth.

The Brenton ProSeries Mach-2 uses a Rexroth integrated motor/drive and motion logic control platform to improve machine performance, save space, lower costs and save energy.

According to Grinager, the multi-axis machine reaches speeds of up to 25 cases/min and can accommodate a variety of cases, including RSC, HSC, tray, wrap-around, knock-down and harness for cartons, bottles, cans and tubs. During operation, an empty case blank is picked by vacuum and set in the machine. The case is moved through loading and sealing sections of the machine, which are powered by servo-driven flap traps. After loading, the full case is indexed through a compression and sealing area. The completed case is then discharged on the customer’s takeaway conveyor.

Brenton developed the Mach-2 case packer to minimize the environmental impact of packaging operations through the appropriate use of electric servodrives, resulting in lower energy consumption—including zero air consumption—and less product and packaging waste. The company worked closely with local distributor Motion Tech Automation during this phase of the development.

“We recommended [the] compact, scalable IndraDrive Mi integrated motor/drive system, which is an innovative, cost-effective and simple solution that satisfies the design challenges for today’s modular and high-performance packaging equipment,” said Shawn Nelson, sales engineer at Motion Tech.

Designed with sustainability in mind, the servos were sized to work out of the box as the most cost-effective solution. A holistic approach was taken, with motor drive and gearing all playing a role to reduce the power requirements of the machine. On average, the Mach-2 is expected to generate energy savings of up to 25% compared with the first generation machine.

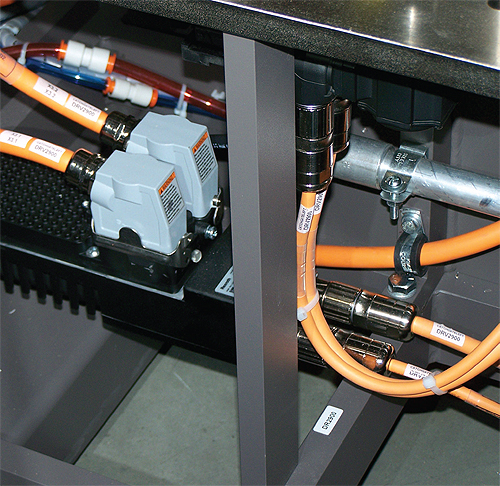

Nelson said that the IndraDrive Mi system combines each servomotor and drive amplifier into one compact unit mounted directly on the machine, outside of the control cabinet. A single cable running from the cabinet is daisy-chained to each motor/drive unit and provides both power and communication. As a result, this design has the potential to reduce a machine’s cabling needs by more than 80%. The unit is also 50% smaller than a traditional servo system, which uses a separate servodrive and motor. This architecture also eliminates the need for an air conditioning unit from the control cabinet and the need to maintain or replace expensive filters.

Conventional servodrives are typically mounted in a large external control cabinet and are connected to the individual servomotors by separate communications, power and feedback cabling that must be mounted and run through large wire ways that clutter the machine.

“Our machine has a cleaner appearance without all the wires running to and from the electrical cabinet,” said Grinager. “Because of the small integrated motor/drive units and fewer cables, the machine features an attractive walk-in design that allows easy access for the operator to clean and maintain it.”

“The integrated motor/drive units help reduce the size of the electrical cabinet,” said Nelson. Because the drives are integrated directly with the motors outside of the control cabinet, design engineers reduced the size of the Mach-2 control cabinet by 25%. Up to 20 drive units can be connected from one power supply without additional distribution boxes. The drive easily accommodates the multiple functions of the Mach-2 case packer without increasing the size of the electrical cabinet. In addition, integrating the drive control and motor into one component provides a more flexible plug-and-play capability. More motors can easily be installed for machine upgrades or other machine configurations such as unique infeeds, said Nelson.

Grinager said there was one additional advantage to using the motor/drive system: versatility. Although the system allowed Brenton to design a machine with a significantly smaller footprint, reducing size by about 30%, the space in the machine’s case compression area was too compact to accommodate even the smallest integrated motor/drive unit. The solution was the IndraDrive Mi KMS, a distributed drive unit that can be mounted on the machine near a conventional servo motor and seamlessly connected with the Indradrive Mi cables.

Brenton Engineering’s innovative controls team also used the IndraDrive Mi distributed input/output system, said Nelson. Having four I/O outputs directly on the motor eliminated the need for extra wiring and other costs associated with purchasing separate I/O outputs from another vendor.

Rexroth’s integrated motor/drive system helped Brenton Engineering cut out more than 200 moving parts, reducing component costs by a third.

Motion synchronization and control are handled through SERCOS digital communication to each servodrive. The case packer uses synchronous, electronic camming technology provided by the IndraMotion MLC L40 motion logic controller. The controller features Flex Profile function, seamlessly combining synchronous and time-based steps into a single data function that optimizes system performance and recovery and also reduces the changeover time.

In addition, the IndraControl VEP 40 HMI, which was mounted to the frame instead of the control panel, integrates easily with the rest of the machine components using OPC communications. The VEP 40 is an embedded terminal with a Windows CE operating system and a high-performance 12-in. TFT touchscreen display.

“The Mach-2 has become a standard for Brenton Engineering,” said Grinager. “[The] technology allowed us to simplify the design of the Mach-2 case packer and reduce extraneous parts and energy consumption in the machine. The ability to daisy-chain servo motors led to less wiring and contributed to a smaller electrical cabinet and ultimately an overall smaller machine footprint.”

Discuss this on The Engineering Exchange:

Brenton Engineering

www.brentonengineering.com

Bosch Rexroth Corp.

www.boschrexroth-us.com

Motion Tech Automation Inc.

www.motiontech.com

::Design World::

Filed Under: AUTOMATION, Green engineering • renewable energy • sustainability, Energy management + harvesting, Packaging, Motion control • motor controls

Tell Us What You Think!