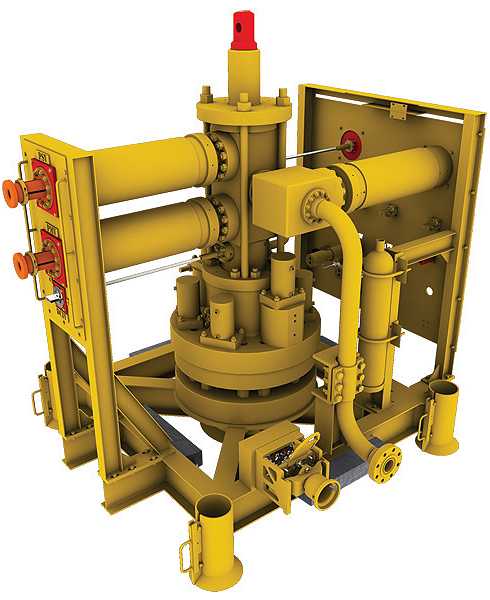

Argus Subsea, Houston, Tex., developed its AZ-10 fully concentric, vertical mono-bore subsea tree design for rapid field deployment. For marginal and smaller fields that need off-the-shelf hardware, the subsea tree can also be run on any rig, regardless of the size of the floor or base of the hull water-access opening (moon pool) or accessibility through a V-door or port side. Anywhere a rig can power a blowout preventer (BOP), the AZ-10 can operate effectively. The unit can go into operation quickly, thanks to its standard horizontal tree design and universal tubing hanger system that runs in any 18-3/4 in., 10,000 or 15,000 psi wellhead.

AMLOK rod lock highlighted on tree. Each rod lock operates to 3000 psi and provides 50,000 pounds of axial holding force at depths of 5000-6000 ft.

The hanger system operates on a lock and seal system that uses mechanical and hydraulic sealing within the tubing hanger. A key component is the AMLOK® hydraulic rod lock, from Advanced Machine & Engineering (AME) of Rockford, Ill. Several challenges were apparent with the subsea trees and a few were not. The obvious obstacles were the depth and the pressures involved. The maximum load was to be 3000 psi and the axial holding force approximately 50,000 lb at typical depths in the 5000-6000 ft range. AME engineered the rod locks from 4140-steel with electroless nickel-plating and a specially formulated two-part epoxy to create a completely sealed unit. Marine grade lubricant was used.

The construction of the rod lock also needed to accommodate the challenges of force over distance in a number of installation conditions. It was necessary for AME engineers to create a one-size-works-all unit and this presented considerable application engineering challenges.

The AMLOK rod locks needed to work over the entire range of performance scenarios; 1500 psi release and 3000 psi compressive were needed to satisfy all conditions. Two to four of these locks are used per tree. They have been used successfully on many installations of the AZ-10, connecting to a number of wellhead equipment brands.

AME rod locks are actuated by a spring/collet mechanism upon loss of hydraulic power and unclamped by the restored pressure. They are built to accomplish a mechanical locking, holding a cylinder rod or machine shaft in position, up to the rated load, until power is restored and the locking mechanism released.

Argus Subsea

www.argussubsea.com

Advanced Machine & Engineering

www.ame.com

::Design World::

Filed Under: Hydraulic equipment + components, FLUID POWER

Tell Us What You Think!