IDI Composites International announced the installation of a new automated bulk molding compound (BMC) production line at its Noblesville, IN manufacturing facility.

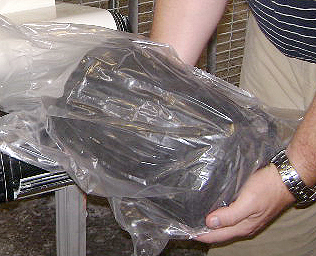

IDI’s new automated BMC line forms the material into preforms, then automatically bags and heat seals them.

The new line is the culmination of a 2-year project spearheaded by Chris Templin, IDI BMC Operations Manager at Noblesville. He cites a number of benefits that the new equipment brings to the BMC production process.

There is a substantial safety improvement factor involved, as the equipment eliminates the need for operators to touch the material during formulation or packaging. The machine forms the material into pre-forms, automatically bags and heat seals them, and presents the bags to operators who load them into skidded boxes.

This hermetic sealing of the finished product helps decrease degradation of the material, which was previously manually handled and put into bags that were also manually sealed.

The equipment has several production advantages, the foremost of which is the reduction of contamination potential, primarily because IDI has eliminated the handling of the raw material by line operators. The machine also provides conformity of the finished BMC pre-form in terms of size and weight. Each package is now a consistent weight and size.

IDI Composites

www.idicomposites.com

::Design World::

Filed Under: Factory automation, AUTOMATION, Conveyors, Materials • advanced

Tell Us What You Think!