In 2019, a new public project will be coming to Austin, Texas. The interactive sculpture, Kempelen’s Owls, will feature two Texas great-horned owls, each standing 10-ft tall and perched atop dodecahedrons.

The slewing ring enables the head of the owl to rotate and is activated with a hidden mechanism that will allow visitors to secretly turn the heads of the birds.

What makes Kempelen’s Owls unique is a hidden mechanism that will allow visitors to secretly turn the heads of the birds. “The mechanism is hidden in plain sight and readily accessible,’’ said Dan Sternof Beyer, Founder and Creative Director of New American Public Art (NAPA), a multi-disciplinary studio that conceptualizes, designs, fabricates and installs interactive projects.

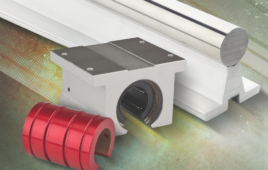

The critical component that allows the head of the owl to spin is a slewing ring manufactured by igus. The PRT-01-300 ring is lubrication free, and has a high load capacity and wear resistance. “The bearing that spins the head of the owl is one of the most important pieces of the project, physically and conceptually,’’ Sternof Beyer said.

The challenge, Sternof Beyer said, was finding a bearing that could meet all the requirements needed for this application.

“For this bearing, we needed a particular set of qualities,’’ he said. “We needed a bearing that was very wide to allow for mechanical and lighting elements to pass through it. This bearing needed to support a large axial and dynamic range to be as safe in public as possible. It also needed to be as maintenance free as possible while being subjected to an outdoor environment. The demanding list of qualities rules out 90% of the bearings in the market.”

The sliding surface of the slewing rings is made with iglide J material, which is characterized by chemical resistance, vibration dampening, and low moisture absorption. The ring has an axial static load of 27,000 newtons and an axial dynamic load of 7,000 newtons.

“The large outside diameter (450 millimeters) allows for less cantilevered sculptural material and the large inside diameter (430 millimeters) allows us to pass through fiber optic cable, which light the owls’ eyes at night,’’ Sternof Beyer said. “The axial and dynamic range are more than enough for the weight of the owl head, but also gives us assurance if the public decides to pull on the head.”

These slewing ring bearings are used in an assortment of industrial applications. They have been used in a handling system for a semiconductor carrier, a self-rotating light, an automatic welding plant, and a machine tool control panel. They are also used in a variety of industries, such as medical, packaging, food processing, solar, seating and material handling.

Each owl includes a slewing ring with a large outside and inside diameter, which was critical to the construction of the interactive exhibit.

The team designing the sculpture began by 3D scanning a stuffed owl from the University of Texas. “The biggest challenge was attempting to reach the perfection of the digital model, considering the real-world tolerances and fabrication constraints,’’ Sternof Beyer said.

NAPA was accepted into the Autodesk Technology Center Residency Program at the Autodesk BUILD Space in Boston. Its team made prototypes using 3Dprinting, laser cut wood and plastic, and even large-scale plain carbon steel. Each sculpture is comprised of more than 3,000 individual pieces.

“The prototype process was invaluable,’’ Sternof Beyer said. “It allowed us to fail early.”

Unlike many complex engineering projects, Kempelen’s Owls will be open sourced. When the project is complete, anyone will be able to download the fully engineered model and see all the technical data, materials and engineering solutions the NAPA team employed.

“It would make us very happy if this work became a well-known library of creative solutions, one that can be referenced and leveraged for years to come,’’ Sternof Beyer said.

igus

igus.com

Filed Under: Bearings