There is no denying the benefits of lithium-ion batteries over their lead acid and NiCd precursors. The energy density, cycle life, size and weight of lithium ion batteries have enabled new technologies, such as electric vehicles and personal technologies like cell phones, and contributed to the advancement of products in existing markets. However, continued market growth remains dependent on the ability to further improve energy density, while maintaining current cost and cycle lifetime performance. This is why many consider battery development to be one of the most high-growth global industries, and why manufacturers and product brand makers search for the future in battery manufacturing.

The Challenge

Lithium-ion batteries are a dominant source of energy storage for mobile applications including wearable devices, portable electronics, cordless power tools and electric vehicles. For decades, advancements have been made to improve cycle lifetime, cost and performance, but energy density, defined by the measure of how much energy can be stored in a battery, has remained an elusive challenge.

Today’s lithium ion batteries are made primarily with graphite carbon anodes, which is one of the components in which battery energy is stored. Although graphite anodes provide durability, the material is limited in its capacity to absorb ions and is the main limiting factor in improving energy density.

The Opportunity

Increased energy density is the key to providing battery solutions that can advance tomorrow’s most promising markets, spanning technology, automotive, defense and aerospace. Examples include battery-powered vehicles capable of driving further on a single charge, battery-powered commercial air travel becoming viable, and wearable devices made even smaller which would make them more appealing to consumers.

Manufacturers have been searching for alternative anode materials that have the capability to increase battery energy density, while maintaining other performance requirements. Silicon has been proven to increase energy density in anodes, but presents another challenge of protecting the material against absorbing too many ions, too quickly, resulting in material degradation over time. That restriction imposes challenges on the battery cycle life.

Turning Potential to Reality

The development of silicon anodes for lithium ion batteries has also been hampered by commercially scalable methods to produce nanostructured materials with well-defined size and morphology, with characteristic sizes below 150 nm. Traditional top-down methods, including ball milling, are inexpensive and yield silicon materials with high degrees of agglomeration, relatively large particle sizes, and poorly defined morphologies and surfaces. Metal assisted chemical etching is an alternative method that has been explored to synthesize silicon nanomaterials. Control over the morphology, etching direction, mass transfer issues, and the requirement for highly toxic reagents such as hydrofluoric acid limit the commercialization of that method. Meanwhile, bottom-up methods such as chemical vapor deposition (CVD) methods have also been the subject of intense exploration. CVD-based synthesis yields well-defined particle sizes and a diverse array of nanostructured architectures including nanoparticles (NPs), nanowires (NWs), and thin films. A major hindrance to using CVD methods has been high capital cost, low yields, and the use of hazardous and pyrophoric gaseous silicon feedstocks such as silane, SiH4.

The solution may lie in a silicon-carbon hybrid anode, made with nanostructures that store more lithium ions, while reducing the potential for damage as the silicon expands. These hybrid nanostructures include silicon-coated carbon nanotubes, core-shell nanostructures, and carbon coated silicon nanowires grown by electrospinning or by the vapor-liquid-process. Cyclohexasilane, CHS, enables commercially viable approaches to manufacture these nanostructures due to its ability to be readily functionalized, more ideal handling conditions, and more favorable reaction conditions. All of these merits could result in single-step processing and roll-to-roll manufacturing. This “drop-in” replacement to existing manufacturing processes would offer a means to reduce costs and avoid using CVD methods that have high capital costs.

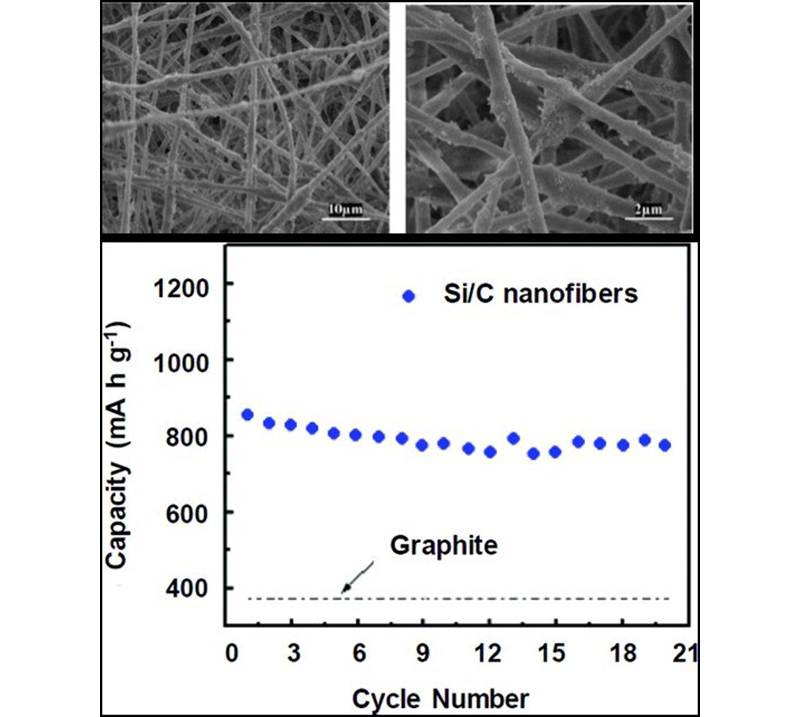

The figure below highlights the merits of this approach, illustrating that with relatively low silicon incorporation into the anode structure, an increase in the energy density by roughly 3x is readily achieved, while maintaining good cycle life.2

Moreover, the resulting silicon nanostructured morphology can be readily tailored to deliver nanofibers or nanoparticles with a desired size and conductive carbon additive. Silicon thin films are also a possibility, and we envision deposition mechanisms that alleviate some of the delamination issues that have plagued previous efforts.

What’s Next?

The lithium-ion battery market is projected to grow at a CAGR of 13.7% between 2017 and 2022, to a value of USD 67.7 billion. As consumer demand grows for battery-enabled technology, manufacturers are investing in battery research and development, with the goal of speeding the advancement of energy density in lithium-ion batteries.

Silicon-based anodes figure to capture an increasing share of that market, and R&D efforts in that area among major global players and startups is increasing considerably, primarily from battery manufacturers, auto makers and more. As energy density improves, we can look forward to product advancements across the technology sector, and the introduction of products not yet imagined.

- X. Zhang et al., “Electrospun Nanofiber-Based Anodes, Cathodes, and Separators for Advanced Lithium-Ion Batteries”, Polymer Reviews, 51, 234-264 (2011).

Filed Under: Rapid prototyping