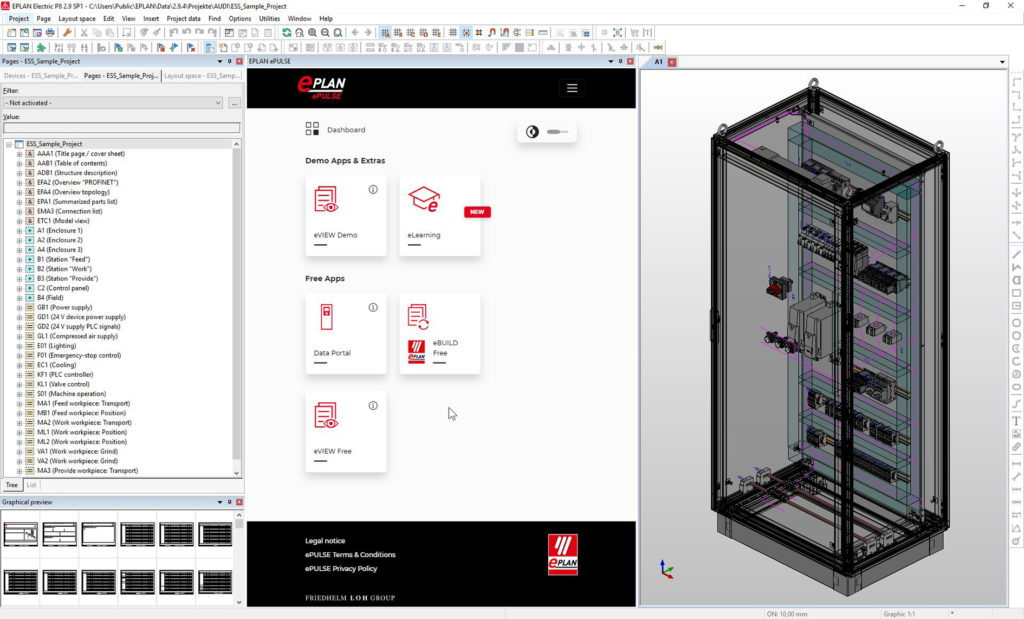

The newest version of EPLAN Data Portal, which provides users with component and device data for design engineering over the web, was released in early June 2020. The Portal is now exclusively integrated into the EPLAN ePulse cloud environment. Electrical engineers and fluid design engineers select the device data they need and can transfer it directly into their EPLAN Projects, reducing the efforts needed for design engineering and ensuring standardized data for documentation. A completely new user interface with an intuitive search and smart suggestion function makes using the Portal easier, faster and more convenient than ever.Timm Hauschke.jpg: Director Cloud Business Master Data Timm Hauschke says: »The direct transfer of the offered component data into EPLAN documentation reduces the effort required for designing for our customers.»

The new EPLAN Data Portal is launched and this web-based application is now exclusively available in the EPLAN ePulse cloud environment. Users of the current EPLAN Platform, Version 2.9 can access it after registering at www.epulse.com, and they benefit from immediate online access to high-quality product catalogs from a continually growing pool of renowned component manufacturers. Director Cloud Business Master Data Timm Hauschke says: »The direct transfer of the offered component data into the EPLAN documentation reduces the effort required for designing for our customers and increases the quality of the machine and plant system documentation.» All solutions anchored in the EPLAN Platform access the web service in equal measure.

The new EPLAN Data Portal has been directly integrated into the EPLAN ePulse cloud environment since June. The new user interface with an intuitive search and smart suggestion function makes using the Portal easier, faster and more convenient than ever.

Reaching the goal even faster.

EPLAN has made it even easier to use and navigate through the comprehensive range of stored device data with its new user interface. An intuitive search function offers fast and practical support. A suggestion function – for instance; for product groups, components or manufacturers – has also been integrated, with a look and feel similar to common search engines. This saves time when designing and leads to quick results. Another practical benefit: calculation programs such as Rittal Therm or selectors from Schneider Electric have already been integrated with the manufacturers´ designs, making it easier to select the right product. Users can find what they are looking for in an even more targeted manner and can discover useful additions or alternatives with just a few clicks.

Current data in the cloud

The integration of the EPLAN Data Portal into EPLAN ePulse offers a number of advantages right off the bat: updates can be imported at any time – whether it be in the application itself or in the portfolio of more than three hundred component manufacturers that already offer around one million devices´ data for direct download. Additionally, more than 1.5 million variants of devices can be called up via integrated configurators. Another practical benefit for users is that their software is always up-to-date in the cloud environment.

Standards ensure more depth of data

Standardized component data is indispensable for creating efficient processes. When control cabinets are being designed in 3D, wire lengths automatically calculated, or mounting plates processed by machines, standardized device data is required. As Hauschke explains: »The EPLAN Data Standard supplements proven classification standards for device data, for instance eCl@ss Advanced, by making them fit for practical use. It ensures the consistent use of data throughout all engineering and manufacturing processes – moving towards a fully integrated value chain.» Users benefit from considerable time savings that have an effect from the start of project planning all the way through commissioning. After all, the representation of a device in various system diagrams is based on a uniform data source – the single source of truth.

EPLAN Data Portal is a portal for exchange between component manufacturers and electrical engineers and fluid design engineers, providing master data for downloading. Aside from alphanumeric component data, it also includes schematic macros, device information in multiple languages, preview images, documentation and additional information.

EPLAN

www.epulse.com

Filed Under: NEWS • PROFILES • EDITORIALS