The advanced high-strength steel market is growing as automotive applications change and develop, and the Steel Market Development Institute (SMDI) has put together its annual data sheet showing the present and future state of the industry.

The 2016 Steel Industry Technology Roadmap for Automotive covers the need for fuel economy considerations and for lighter steel particularly. As standards for emissions become stricter, steel makers are looking into reducing mass. Vehicle mass affects only about 11 percent of energy loss, but material selection can effect this portion, and steel often makes up more than 50 percent of the mass of a vehicle.

One recent design project from SMDI is the lightweight twist beam, created by Multimatic Engineering, which offers a 30 percent mass reduction from the OEM baseline assembly and a small (12-15 percent) cost premium. Steel-intensive designs for a front lower control arm, using a clamshell design, was also shown to have a 34 percent cost reduction and to match the weight of a best in class aluminum equivalent.

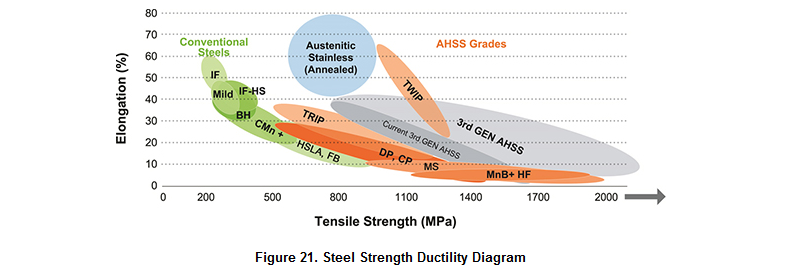

Image credit: Steel Market Development Institute

“Steel remains the fastest growing material in automotive applications and the North American steel industry continues to develop new grades and advanced manufacturing technologies to respond to the changing needs of automakers, as it is an important material in the designer’s toolbox,” said Jody Hall, vice president, automotive for SMDI.

SMDI is a business unit of the American Iron and Steel Institute, and is devoted to the promotion of the steel market.

The complete report can be found here.

Filed Under: Materials • advanced