By: Sheldon Yourist, Senior Director of Global Design, Graham Packaging and Balaji Jayaseelan, Director of Sustainability and Regulatory Affairs, Graham Packaging

In recent years, plastic has come under increased scrutiny due to low recyclability rates and the growing amount of plastic waste in the natural environment. While manufacturers are stepping up efforts to meet consumer demand for more sustainable solutions, there are still significant challenges at every level of the recycling process that build barriers to recyclability.

In recent years, plastic has come under increased scrutiny due to low recyclability rates and the growing amount of plastic waste in the natural environment. While manufacturers are stepping up efforts to meet consumer demand for more sustainable solutions, there are still significant challenges at every level of the recycling process that build barriers to recyclability.

Over the years, package designers have seen additional demands placed on their talents and skill set. Not only are they tasked with crafting eye-catching designs that differentiate products at point of sale, but they are also under increased pressure to create sustainable solutions that offer additional shelf appeal to environmentally conscious consumers. There is no one solution to success. It involves the use of art, communication, engineering, technology and manufacturing to optimize the development of customized, sustainable packaging solutions.

Packaging manufacturers should broaden their perspectives beyond just recyclability to complete sustainability. What used to be considered a cradle-to-grave process is now a cradle-to-cradle solution that evaluates and optimizes every aspect of the supply chain to improve circularity. Many consumer brands and manufacturers have signed the Ellen MacArthur Foundation pledge to ensure plastic materials used in new packages are 100% reusable, recyclable or biodegradable by 2025.

Beyond post-consumer recycling

One of the greatest challenges packaging companies face is the lack of access to recycled content — particularly post-consumer recycling (PCR). Low recycling rates and a lack of consumer education regarding how to recycle properly has made PCR a scarce commodity. Luckily, there are alternative sources for obtaining recycled content.

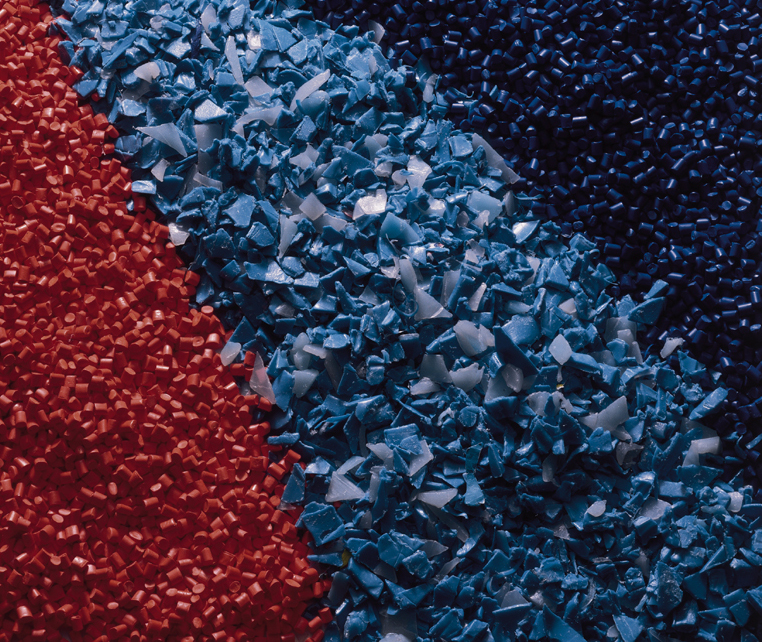

Post-industrial recycling (PIR) is another source of recycled content that is equally important in reducing the carbon footprint and lowering greenhouse gas emissions. PIR is derived from the waste generated from the original manufacturing process that is used again in the same material. Although PIR is often seen as a less attractive solution for brands, it allows for more recycled content to be used in the manufacturing process at a lower carbon footprint.

For the manufacturer, post-industrial recycling (PIR) often requires less energy to convert material into a new, usable package. Additional benefits include freight savings, less mixed-material contamination and lower cost for conversion (saved energy for cleaning, sorting and interim conversion of flakes to pellets). PIR can offset the demand for virgin materials and the added freight to sell off PIR and bring in new materials.

A tremendous advantage of PIR is the ease of access to a distribution network. Scrap material can be easily collected and sorted in the facility that it comes out of and quickly sent to be reprocessed into a raw material form.

Keeping oceans clean starts with preventing waste — including plastic — from entering them. Having the ability to recycle salvaged plastics is even better. Rescuing ocean-bound plastics (OBP) involves taking materials that are at risk of becoming ocean pollution and turning them into a reusable plastic resin.

Every pound of rescued OBP is pollution transformed into a recyclable resource. OBP can be refined to quality levels with up to 100% inclusion in nearly any application where HDPE/PET is the preferred material. This versatile resin can be used for both injection and blow-molding products, making it suitable for a wide range of packaging applications.

Reducing plastic in bottles

Due to the challenges of securing recycled content — particularly food-grade material — manufacturers are finding innovative ways to lightweight their packaging in an effort to significantly reduce the amount of material needed in each package. In addition to shrinking package weight, lightweighting allows more product to be shipped in one truck.

There are several ways companies like Graham Packaging are reducing plastic content, including:

Vertically Applied Processing (VAP) — This process involves extrusion blow molding with vertical bands that can be adjusted to increase or decrease bottle wall thickness in desired locations. It allows polyolefins to be strategically placed throughout the bottle. Concentrating vertical stripes around the corners allows it to take on more weight while reducing the amount of material needed at the base and throughout the entire bottle.

ThermaSet — Lightweighting has also been proven to be successful in hot-fill food processes. This heat-set process allows PET containers to be used in challenging fill processes like hot fill, pasteurized and retort where glass is typically used. Because of its lighter weight and smaller footprint than current glass jars, 40% more ThermaSet PET jars can be put on a single truck. They also need less packaging and fuel during transport while being fully reusable and recyclable.

Eliminating grips and handles — By simply removing the grips and handles from plastic bottles, companies can significantly reduce package weight. One spirits company decided to remove the handle from its bottle, resulting in a 15% weight reduction. By making this simple change, the annual material savings for this single product was equivalent in weight to seven Boeing 747 jets.

While taking weight out of bottles is one way to promote sustainability, manufacturers are also seeking out alternatives that encourage consumers to reuse bottles in an effort to eliminate downstream waste. One way to promote reuse is to add texture. This process helps extend the “like new” appearance of a bottle and is less likely to be discarded after a single use.

Adding texture that takes on the appearance of bubbles at the base of a bottle helps to heighten shelf appeal, while also boosting reuse. Bottles with added texture have shown to reduce scuffing by 75% and can be reused up to 25 times compared to non-textured counterparts.

Mixed material recyclability

Plastic packaging often includes various other materials that complement the product both aesthetically and functionally. To make sure a product is completely recyclable, plastic manufacturers must work with their vendor partners to ensure packing will not be rejected in recycling streams because of labeling, coloring, adhesives or attachments. Knowing this, plastic packaging manufacturers are now taking steps to proactively address these concerns with customer in order to guarantee a more sustainable outcome.

Changes to packaging design never occur in a bubble. Insights and data, driven by a consumer lens, contribute to research and development, technology and future innovations. Understanding what motivates consumers at the point of sale helps drive advancements in sustainable design.

Supporting a circular economy requires bringing together customers, suppliers and manufacturers to create sustainable products that are good for the environment and future generations. By exploring new shapes, processes and technologies, designers can increase recyclability and lightweighting while creating functional features that minimize the environmental impact of packaging. These efforts allow manufacturers to deliver on customers’ design goals while reducing their overall environmental footprint.

Filed Under: Green engineering • renewable energy • sustainability