by Paul J. Heney, Editorial Director

North Sea wind farm installations will soon get a hand from a six-legged ship capable of raising itself over water as deep as 75 m. Lifting the ship above the water is necessary to stabilize it as workers assemble the tower, nacelle, and rotor.

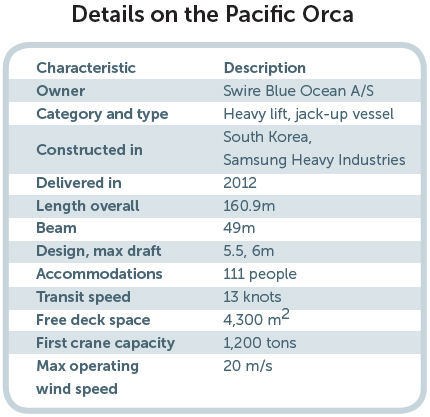

“The Pacific Orca is the largest wind farm installation ship ever built,” said Jan Schreiber, Germanischer Lloyd’s (GL) new Ship Type Expert for Offshore Service and Working Vessels. “Her capacity is enormous. She can carry and install up to 12, 3.6-MW wind turbines.”

For future projects, the ship will also be able to install larger turbines, those with a rated output of up to 10 MW.

GL Noble Denton engineered the legs, spud-cans, and the jacking system and integrated the components into the ship’s hull. Future-Ship, another GL company, carried out global strength and fatigue analyses for the ship afloat and was responsible for owner consultancy.

The ship raised in harbor, Pacific Orca can lift itself up to 17 m above sea level. This minimizes the impact of waves and wind during turbine installations.

Schreiber said his company also assisted by publishing new rules for Hull Structures of offshore service vessels in 2010. The rules have recently been supplemented by a set of classifications for crew boats and offshore wind-farm-service craft.

The combination of the vessel’s design criteria transit speed, lifting capacity, station keeping and jacking speed set up new industry standards. For instance, it can be deployed to conduct wind farm installation wind velocity of 20 m/sec (use of crane) and significant wave heights of 2.5 m (jacking) It is designed to withstand extremely rough weather and sea conditions in jacked-up mode.

The vessel is powered by eight diesel-electric main generator sets, each rated at 3.2 MW. A dynamic positioning class-two control system automatically maintains the position and heading of the vessel. For maneuvering, the vessel is fitted with four 3.8-MW azimuth stern thrusters, two 2.2-MW bow retractable azimuth thrusters, and two 2.2-MW bow tunnel thrusters.

Filed Under: Green engineering • renewable energy • sustainability, Energy management + harvesting

Tell Us What You Think!