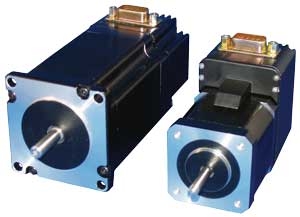

Nippon Pulse America introduces PRO Series NEMA 17 integrated motor/drivers. The drives are ideal for machine designs where an incorporated motor/driver helps conserve space. A 42 mm Hybrid motor with attached drive electronics, yields a compact, RoHS compliant package.

PRO Series hybrid stepper motors are precision designed for medical technologies and semiconductor manufacturing applications. They deliver accurate open loop control for high performance positioning applications. Two models, PRO 42AP 1/500 microstepping, and PRO 42BP 1/8 microstepping are available.

The PRO series motor/driver package provides high torque density and simplified operation through attached drive electronics. This can remove the need to run motor power management cabling through the machine, and may reduce the potential for electrical noise.

These motors are available in case lengths of 40, 48, and 60 mm. Depending on the case length, the PRO Series Size 17 motor can produce maximum holding torques (bipolar) ranging from 300 to 440 mNm.

PRO Series is available in two models: AP 100,000 steps and BP 16,000 steps resolution. Precision-honed stators and ground rotors for tight air gap and maximum performance; and simple, rugged, ball bearing construction provide high reliability and long service life. An attached encoder is optional on both AP & BP models. Selectable PFD (Percent of Fast Decay) is available with the advanced AP version.

Filed Under: Semiconductor manufacture, Medical-device manufacture, Motion control • motor controls, Motors • stepper

Tell Us What You Think!