The paperboard container industry is highly competitive; machine builders continuously look for ways to improve the function and operation of the equipment they build. Hycorr Machine Corp., Kalamazoo, Mich., is one of those companies and builds corrugated box-making machinery. Recently, the engineering team was tasked with improving the overall controls package on the company’s line of rotary die-cutters. In particular, the servo system and controls needed an upgrade. The previous technology functioned satisfactorily, but the engineers sought to reduce costs and component size without a loss in performance on their machines.

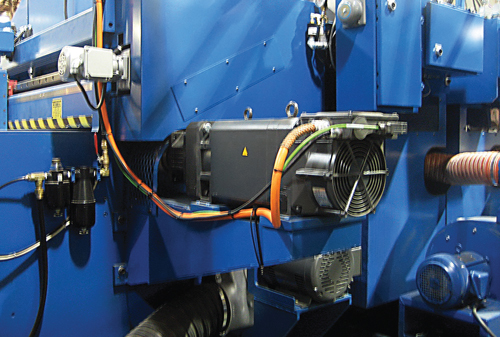

Hycorr rotary die-cutter, shown with four print stations, dwell section and die-cut section, in use at a major supplier to the corrugated and other packaging market segments.

The engineers investigated a new system, one that would not only reduce servo drive system and related energy costs, but also integrate with both the programmable logic controller (PLC) and human-machine interface (HMI) functions.

The package under consideration included servomotors, Sinamics® S120 servo drives, and a Simotion® D motion controller with PLC function from Siemens. Said Mike Walter, electrical engineer, Hycorr, ?At first, we were only considering this new system for the motion platform. We needed a servo system that would eliminate some gears and maintain the tight tolerances our customers expected for printing and die cutting. We really needed a system with built-in rotary motion function.”

In the proposed implementation, each component (motion, PLC and HMI) had built-in connectivity to the others. Overall, the savings for Hycorr was calculated to be approximately 50%. In addition, these components reduced control cabinet space requirements by 30%. As Walter put it, “The components were smaller. With the combination of the active interface module and active line module, we eliminated the need for line reactors or line filters.”

Siemens Simotion Shaftless Standard was used to design and integrate the torque motors and servo drive system of motion control with the machine’s PLC and HMI functionality.

Through the use of the Shaftless Standard, the engineers designed a more modular implementation of the components. The entire engineering file for the first machine was loaded from a single compact flash drive and, with minimal debugging, the engineering on a second machine was completed quickly.

Components used on the machine builds included Siemens Sinamics S120 drives, Simotion D425 motion controller, 1PH7 servomotors and Simatic® S7 PLC for simple Windows-based operator interface. As part of the Shaftless Standard package, Hycorr made custom modifications to the various options offered on its rotary die cutters, without extensive engineering time.

Siemens Industry, Inc.

usa.siemens.com/motioncontrol

::Design World::

Filed Under: Factory automation, Packaging, Motion control • motor controls, Motors (direct-drive) + frameless motors, PLCs + PACs

Tell Us What You Think!