Seal-Lok™ fittings and adapters create reliable, leak-free connections for hydrogen and compressed natural gas (CNG) fuel storage and delivery systems. They suit alternative fuel service cars, trucks, buses and filling stations.

Seal-Lok with H2 technology is for highpressure hydrogen systems. The H2 stud and port is interchangeable with standard SAE J1926 fittings and allows full 360° positioning and sealing at 700 bar/10,000 psi. The sealing arrangement also prevents O-ring extrusion under extreme high pressure.

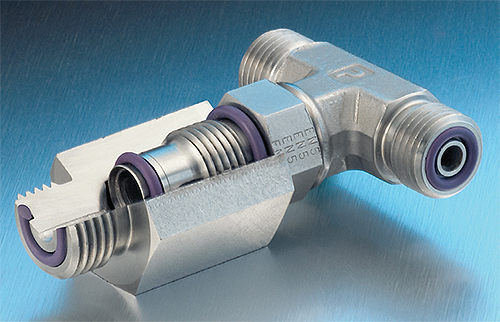

The fittings consist of a nut, sleeve, O-ring and fitting body. The fitting body face contains a high durometer O-ring held captive in a precision-machined groove. As the nut is tightened onto the fitting body, the O-ring is compressed between the body and flat face of the tube flange to form a tight seal.

The fittings meet the requirements of EIHP (European Integrated Hydrogen Project) Revision 12b and EC79/2009 as tested by TÜV. The fittings have been validated in sizes ranging from ¼ in. to ¾ in. (6 mm to 20 mm). Seal-Lok fittings and adapters with tested O-ring compounds are also approved for CNG service up to 350 bar/5,000 psi per ECE R110 and ISO 15500.

The fittings have been tested and approved for assembly using the Parflange tube connection system, which eliminates the need for braze or weld joints by providing a reliable flange or flare tube connection where a potential leak could occur. Parflange technology uses an orbital spindle process that cold forms a 90° flat face on the end of the tube.

Tube Fittings Div., Parker Hannifin Corp.

www.parker.com/tfd

::Design World::

Filed Under: Hydraulic equipment + components, Automotive, Tubing components, Green engineering • renewable energy • sustainability, Seals • O rings, FASTENING • JOINING • locks • latches • pins, Materials • advanced, Energy management + harvesting, Seals

Tell Us What You Think!