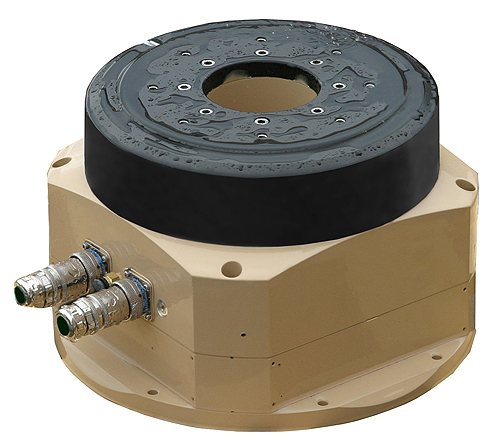

The ASRT is an IP66-rated, direct-drive, sealed rotary stage that provides precise angular positioning in hostile environments where dirt, dust, cutting fluids and fluid jets are present. Applications range from industrial machining automation to precision sensor positioning in hostile environments, and the ASRT is also an effective solution for precise rotary motion in product environmental test and range tracking applications.

The ASRT is offered with either high accuracy encoder or magnetic encoder feedback. Unlimited travel is standard, with an optional limited travel model also available. Three different models cover a wide range of load and torque requirements.

The ASRT series uses Aerotech’s brushless, slotless motor that has no brushes to wear, no gear trains to maintain, and high acceleration and high speeds. The low inertia and zero backlash make the ASRT the ideal solution for applications requiring frequent directional changes. In addition, Aerotech manufactures a wide range of servo amplifiers and advanced controllers to provide a complete, integrated package.

Dual large-diameter bearings are used to maximize performance with respect to tilt error motion (3 arc sec), moment stiffness, and repeatability (1 arc sec). The large diameter bearings permit large payloads (up to 175 kg) without compromising performance.

Maximum rotary speeds are from 100 to 200 rpm. The ASRT includes an electrically grounded shaft and housing to protect against electrical shock and eliminate RF re-radiation, and housing grounding points are included. Circular sealed connectors are standard, while options include desiccant cartridge, air purge, and mounting flange accessory.

A polymer-based paint on the housing and a hard-coated tabletop prevent corrosion. The stage has optional brown, green, grey, black, and white paint colors. Standard operating temperature is 0 to 70°C. Operation below freezing requires the optional air-purge and desiccant, with air-purged stages operational from -20 to 70°C.

Aerotech

www.aerotech.com

::Design World::

Filed Under: Factory automation, Stages • gantries, Motion control • motor controls

Tell Us What You Think!