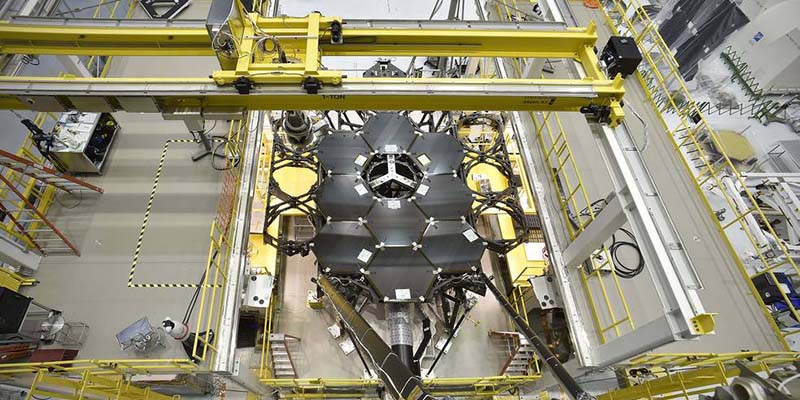

This rare overhead shot of the James Webb Space Telescope shows the nine primary flight mirrors installed on the telescope structure in a clean room at NASA’s Goddard Space Flight Center in Greenbelt, Maryland. Credits: NASA’s Goddard Space Flight Center/Chris Gunn

Inside NASA’s Goddard Space Flight Center’s massive clean room in Greenbelt, Maryland, the ninth flight mirror was installed onto the telescope structure with a robotic arm. This marks the halfway completion point for the James Webb Space Telescope’s segmented primary mirror.

The James Webb Space Telescope team has been working tirelessly to install all 18 of Webb’s mirror segments onto the telescope structure.

“The years of planning and practicing is really paying dividends and the progress is really rewarding for everyone to see,” said NASA’s Optical Telescope Element Manager Lee Feinberg.

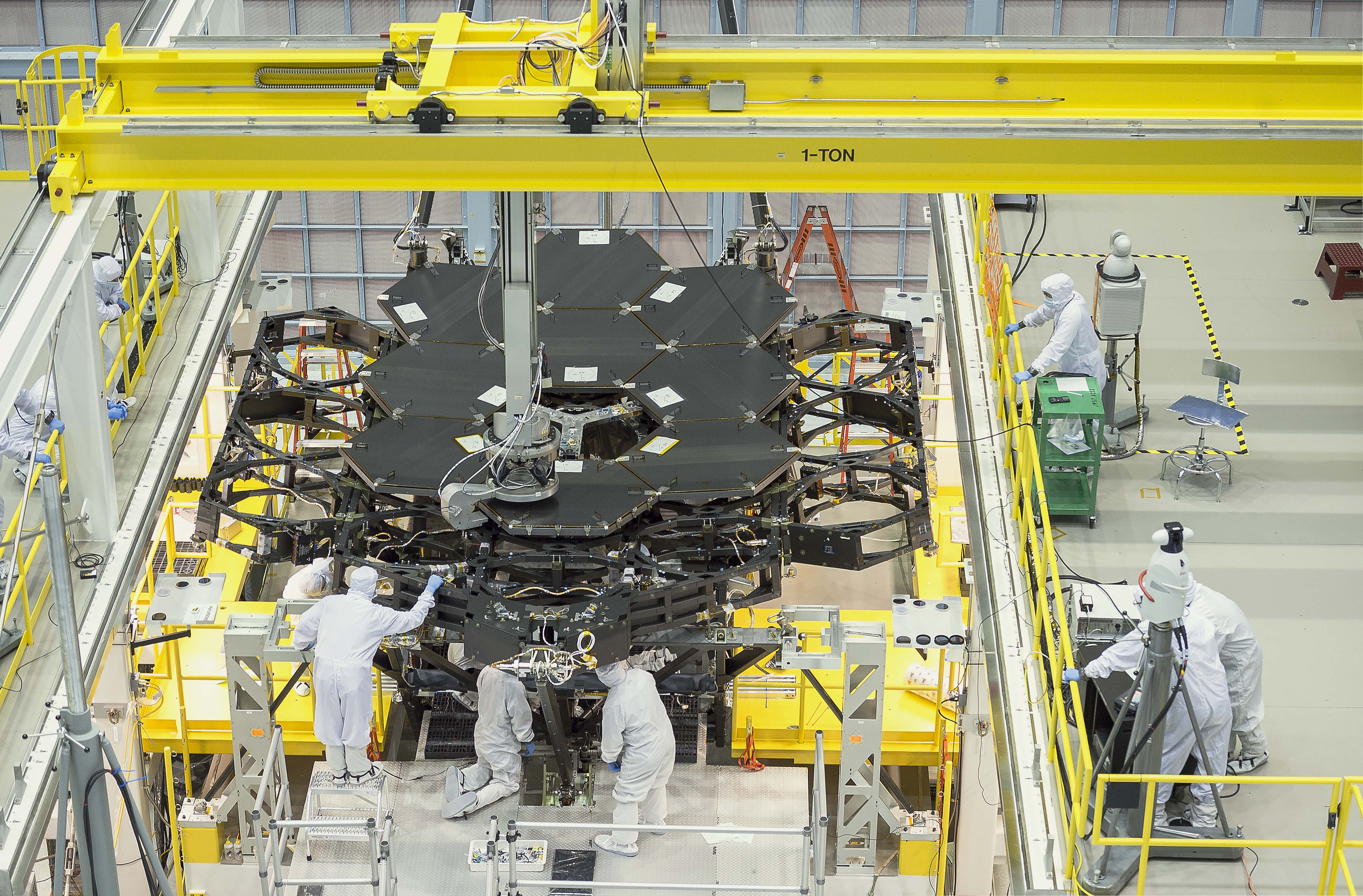

Engineers worked tirelessly to install the ninth primary flight mirror onto the telescope structure. Credits: NASA’s Goddard Space Flight Center/Chris Gunn

In these NASA images, the engineering team is seen using a robotic arm to lift and lower the hexagonal-shaped segment that measures just over 4.2 feet (1.3 meters) across and weighs approximately 88 pounds (40 kilograms).

After being pieced together, the 18 primary mirror segments will work together as one large 21.3-foot (6.5-meter) mirror. The full installation is expected to be complete early in 2016.

The mirrors were built by Ball Aerospace & Technologies Corp., in Boulder, Colorado. Ball is the principal subcontractor to Northrop Grumman for the optical technology and lightweight mirror system.

The installation of the mirrors onto the telescope structure is performed by Harris Corporation of Rochester, New York. Harris Corporation leads integration and testing for the telescope.

The James Webb Space Telescope is the scientific successor to NASA’s Hubble Space Telescope. It will be the most powerful space telescope ever built. Webb is an international project led by NASA with its partners, ESA (the European Space Agency) and the Canadian Space Agency.

Filed Under: Aerospace + defense