JenCNC is written specifically for Animatics SmartMotors providing true robust CNC control for the Automation Marketplace. JenCNC now provides control of X, Y, Z and A (rotary or auxiliary axis) and an additional X-Slave Axis.

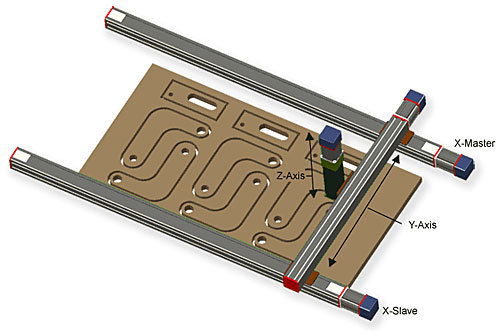

Often times, in wide X-Y axis gantry machines, it is more effective to have two X-Axis motors one on either side of a gantry. In these cases, good closed loop control of each X-Axis is required. In addition, proper homing and error control is needed to insure each side of the X-axis stays in alignment. JenCNC has the dedicated a secondary communications port for the slave axis to allow full control and yet not take from the communications bandwidth of the main X-Axis. This method results in addition of another servo axis with no loss in resolution or precision of the main servos.

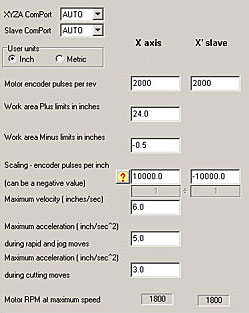

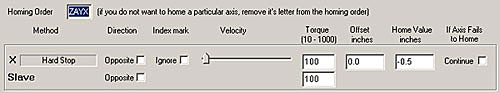

The X-Slave Axis machine settings allow for differences in both gear ratio to load and direction of travel of Homing.

OEMs all over the world are flocking to the JenCNC/SmartMotor solution because it delivers the kernel of Multi-Axis CNC at a fraction of the cost of traditional controls and without a cabinet full of cables and drives. SmartMotors controlled by JenCNC software are driving virtually every type of CNC machine, including, Routers, Milling machines, Plasma, Laser and Waterjet machines, Glue Laying machines, Stitching and Pick & Place machines, and dozens more. The compact and all-inclusive SmartMotors are more reliable than traditional servo controls and the complete replacement of an axis of motion control can be done with a single screwdriver. In the event a motor is damaged, keeping a spare can eliminate down-time and renders annual maintenance contracts obsolete. In fact, an entire 4-axis JenCNC/SmartMotor system could be purchased every year for less than the average cost of a leading manufacturer‚’s annual service call. JenCNC will convert simple CAD .DXF centerline files to G-Code as well as take G-Code directly from popular CAD/CAM programs for more complicated operations involving cutter-compensation or 3-D surfacing.

Filed Under: Motion control • motor controls

Tell Us What You Think!