I am sure you have encountered the term 1U packaging as you peruse catalogs of equipment for almost any field of electronics, from instrumentation to telecom, to standard computer architectures.

Did you ever wonder where this architecture came from and just what is a “U” anyway? And why does it matter?

Standards are wonderful things. For example, they enable us to plug our light bulbs into lamps made by thousands of manufactures around the world. On the other hand, as one of my friends told me, “The wonderful thing about standards is that there are so many of them,” as evidenced by a trip down the light bulb aisle at your home center. He was, by the way, one of those people who seem to make a career from continuously developing next generation standards for the electronics industry.

Electronics designers struggle between using industry standard architectures and using unique architectures that will give them a competitive advantage. Over the years, standard architectures have been broadly adopted to enable equipment to fit into standard racks in data centers and telecom central offices. The height, width, depth, and modularity have been adopted to enable racks to fit next to each other and to use standard computer floor, cooling systems, and cable infrastructure effectively. If a developer uses this architecture, she has off the shelf components to make cabinets, front plates, and systems, significantly reducing cost and speeding development compared to custom hardware.

To help you understand how and why standards exist, let me take a moment to describe the world of industry standards as it applies to electronic packaging.

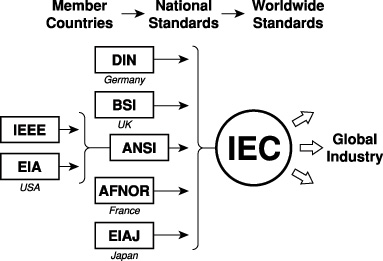

IEC (International Electrotechnical Commission) is the United Nations of standards bodies. Standards proposals are submitted to the IEC from all over the world though individual national standards bodies. Submitted proposals go through an international review process, are then voted on by countries, and then published as IEC standards in English, French, and Russian. The important IEC standard for chassis construction is the IEC 297 series that describe 19-in. rack architecture and the key dimensions that enable modular racks used worldwide in data centers and telecom central offices. Users of this standard architecture are able to mix equipment from multiple manufacturers in their standard racks. The benefit to the equipment producers is that by following these standardized form factors, they know the customer can fit their components into their equipment racks—worldwide.

Proposed standards come to the IEC through national standards organizations like ANSI in the US. Because ANSI does not actually write the standards, it passes through proposals from organizations like the IEEE, EIA, and VITA. IEEE (Institute for Electrical and Electronics Engineers) develops standards around electronic architectures like Ethernet. EIA (Electronic Industry Association) concentrates on standards for testing. VITA (VME International Trade Association) has taken over much of the work around packaging and protocol associated with the VME family of standards. PICMG (PCI Industrial Computer Manufacturers Group) has promoted a family of modular computer specifications called CompactPCI.

You have probably heard of DIN (Deutsches Institut fur Normung) from Germany. Over the years, Germany has been a strong proponent of standard systems to organize many different architectures and component standards. The standard rack architectures were born in Germany, and have been evolving over the years as additional requirements come forward to enhance cooling, EMI containment, and cabling. In the early days, cooling was largely convective with air entering the rack from the bottom rising to the top and exiting. These racks tended to be only 1-ft (300-mm) deep, and can stand against a wall in huts or vaults used by electronic systems like cellular base stations, traffic control, etc. All IO in these systems is from the front.

This style of architecture became known as “Eurocard” architecture. It was standardized in 1984 by the IEC as IEC 297. Vertical height of racks was organized in “U” increments, with 1 U being 1.75 in. Ironic, isn’t it, that the most metric country in the world adopted inch based dimensions. I cannot verify, but I have heard that this was because the tooling that came into use in Germany after the war was inch-based tooling from other countries. Other popular height dimensions are 3U and 6U, 5.25 in. and 10.5 in. respectively. A standard rack can accommodate any combination of U based electronic equipment.

In 1987, the IEEE 1101 working group standardized on 3U and 6U cabinets with common card sizes and connectors, creating an entire industry around standard bus architectures like VME and Multibus. This standard chassis approach spawned an electronic industry made up not only of large suppliers but also a multitude of small, creative companies that could build pieces of a larger system. As an example, Intel or Motorola might build the CPU board, but many other people would build IO boards, power supplies, and other special function boards that just plug into the industry standard system. This approach has been extremely successful and broadly used in industrial controls, medical, military, and outside plant applications. CompactPCI used the same physical platform, but used 2-mm, 5-row backplane connectors to gain many more backplane routing channels than the earlier systems.

This all happened because someone said 1.75 in. is a nice increment for electronic equipment and the 1U packaging was born.

The post Just what is a “U” in electronics design anyway? appeared first on Connector Tips.

Filed Under: Connector Tips