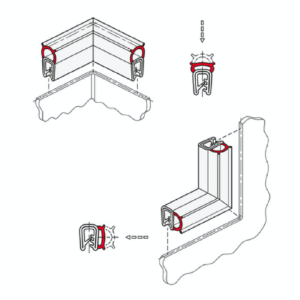

GN 2181 Edge protection seal profile corners

— above type A, below type D

Winco always thinks a step ahead and is now completing its edge protection profile product range with seal profiles that have premade 90° corners.

The standard parts specialist, Winco offers a comprehensive portfolio of edge protection profiles for softening and rounding edges as well as preventing injuries on flaps, doors, access holes and sheet metal edges of all kinds.

The edge protection seals from Winco that include an additional sealing profile feature provide both protection and sealing alike. With corresponding contact pressure, they also offer protection against splash water, dust, and steam while also reducing noise emissions. Depending on the application, edge protection seal profiles can be installed on either cut or bent workpiece edges. The orientation of the seal profile can be selected based on the type, situated on the top or side. The edge protection seal profiles are made of UL-compliant EPDM or of NBR, and the material NBR is particularly well suited for applications in contact with fuels or lubricants.

To also enable right-angled seal contours without the minimum installation radius that is typically necessary, Winco has now expanded its selection with the edge protection seal profile corners GN 2181 with premade 90 0 corners. This eliminates the need for manually cutting the profile free, and the corner joint is tight and durable thanks to the vulcanization. The edge protection seal profile corners can be ordered with various leg lengths and shortened as necessary or extended with the corresponding profile of GN 2180. To ensure a consistent seal, the profiles are installed slightly oversized and “compressed.” As a result, the joints are tightly closed and do not require an adhesive.

As a special service, Winco supplies all edge protection seal profile corners even as single parts, which is particularly useful for special solutions or applications requiring only a small number of parts. Winco also produces edge protection seal profile segments on request, such as in a U or Z shape. Even round or rectangular edge protection seal profile frames in custom dimensions, vulcanized and closed off, can be supplied to meet all the needs of customers with regard to the respective size and shape.

JW Winco

www.jwwinco.com

Filed Under: Seals • O rings, Seals