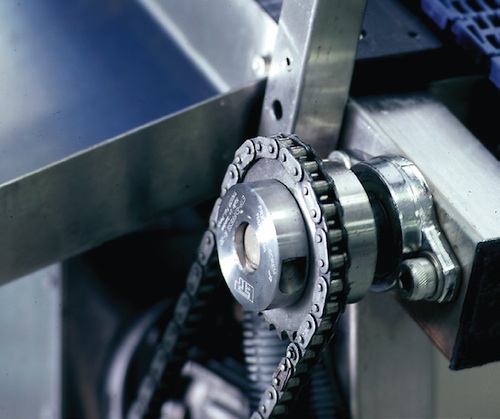

With machine tools increasing the speed they can deliver, components must be able to transmit those higher torque forces. The ETP Express (Model R Stainless Steel) keyless shaft locking bushings are one component with the needed high torque transmission capacity. They are suitable for locking into position gears, pulleys, sprockets and other components in a machine’s power transmission system. Handling torque ranges from 34 to 6400 ft. lb. Made of stainless steel, they won’t corrode or rust in applications with frequent washdowns. They have sealed, clean lines that resist debris collection and clean easily without any special maintenance.

The torque transmission capacity for these stainless steel bushings is two-and-a-half times greater than conventional bushings, made possible by their unique design and stainless steel material. They also have a compact footprint.

These bushings feature just one radial actuation screw for fast mounting, repositioning and phasing of the components to the shafts. They position in seconds and can be readjusted many times just as quickly and without any axial movement of the bushing or component along the keyless shaft. An Allen wrench is all that is required to mount and lock these bushings into place.

The single radial tightening screw provides a solid and more precise connection between shaft and hub unlike conventional shaft locking bushings. The bushings incorporate a double-walled sleeve filled with a pressure medium. When the actuation screw is tightened, the hydraulic pressure medium in the sleeve expands the double walled sleeve, forming a tight, continuous connection between the shaft and mounted component. The bushing aligns precisely without axial movement as it is tightened. Available in 15, 20, 25, 30, 35, 40, 45, 50, 60, 70, 80 mm shaft sizes and 5/8, 3/4 7/8, 1.0, 1-1/8, 1-1/4, 1-3/8, 1-1/2, 1-3/4, 1-15/16, 2.0 in. standard shaft sizes, stainless steel ETP Express-R bushings are a cost-effective choice for new and retrofit applications.

Zero-Max

www.zero-max.com

::Design World::

Filed Under: Bushings • plain (sleeve) bearings, Machine tools + subtractive manufacturing, MECHANICAL POWER TRANSMISSION

Tell Us What You Think!