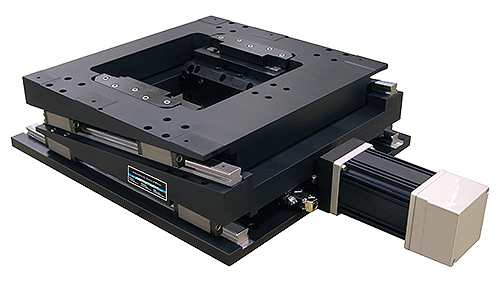

Aerotech’s AVS1000 series stages offer the ideal solution for applications that require positioning of large or heavy loads over very small incremental movements in elevation above a horizontal plane. The low profile and precise motion capability make these stages ideal for use in semiconductor manufacturing and inspection, automated tool alignment, machine vision inspection systems, laser machining applications, and more.

Quality Design Provides Superior Performance

The AVS1000 series provides precise elevation of a load in a vertical plane using a moving-wedge design. The precision machined wedge block converts horizontal movement from a precision-ground ball screw into vertical elevation of the AVS1000 series tabletop. Excellent pitch and yaw characteristics over the length of travel minimize the impact of angular errors. AVS1000 performance includes exceptional resolution (5 nm) and accuracy (±1 µm), with the ability to apply this performance to large loads up to 135 kg.

Sealed linear motion guide bearings with integral wipers are incorporated to provide excellent payload capability, long life, and smooth, precision motion. Stable and parallel vertical motion with no rocking or horizontal deviation of the platform is assured. Careful design of the wedge angle and bearing system allows the AVS1000 series to achieve submicron resolution and still maintain a compact profile.

A Better Approach to Vertical Motion

The vertical lift approach offers an alternative to traditional Z-plane oriented stages. Not only do the AVS1000 series stages offer a lower profile, but the load can also be conveniently accessed from any side due to the large aperture. And by centering the payload over the bearings, there are no cantilevering effects.

Motor and Drives

The AVS1000 series includes Aerotech’s high performance NEMA 34 frame-size BMS series brushless, slotless servomotor. The slotless motor has zero cogging and therefore is optimized for applications requiring very smooth motion.

Aerotech

http://www.aerotech.com/products/liftstages/avs1000.html

::Design World::

Filed Under: Stages • gantries, LINEAR MOTION, Motion control • motor controls

Tell Us What You Think!