SendCutSend announced they have changed the way users can create custom, laser-cut metal parts nationwide.

SendCutSend’s unique business model simplifies metal manufacturing processes by allowing users to create custom, one-off parts, at a fraction of competitors’ prices. By automating the traditional process, SendCutSend provides a quick turnaround for parts that would generally interrupt the workflow of local or mass manufacturers.

Since its inception, SendCutSend has invested in new equipment, including a fiber optic laser. Equipped with a beam finer than a human hair, and a 3kW LED laser engine which can cut up to 2,200 inches per minute.

“We’re a team of fabricators, designers and software engineers who saw a need for fast, accurate parts that we couldn’t make in-house,” said CEO Jim Belosic. “We wanted to bypass the hassle of going through a mass manufacturer for small batch parts, and make it accessible to makers of all capacities.”

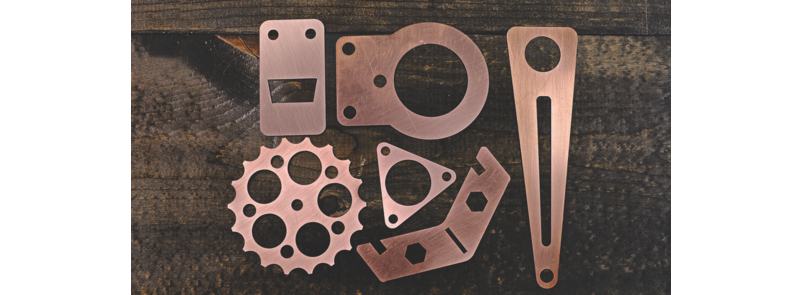

The process works by having users submit their unique designs in any vector-based file format, including ai, dxf, dwg, and svg, and the average turnaround time from file submission to shipment out the door to customers is 24 hours. Designs can be cut into almost any metal or non-organic material, including Stainless Steel, Mild Steel, Aluminum, Copper, Brass, Sterling Silver, Gold, Inconel, Nitinol, Titanium, and Nickel.

In addition to laser cutting, SendCutSend offers precision laser etching and engraving services through its high- speed galvanometer fiber optic laser. SendCutSend can perform surface etching and deep laser-engraving up to 2mm deep on any metal with extreme precision and at speeds 30 times faster than traditional laser etching machines. SendCutSend’s etching and engraving services allow for comprehensive production from start to finish, including part marking, switch panels, decorative applications, or unique logo or branding additions to any metal part.

Cooper parts Credit: SendCutSend

Filed Under: Product design