The tremendous flexibility in LED light tube shapes and sizes, as well as light-effect shapes and brightness, support a wide range of applications that require high reliability, rugged design, aesthetics, low power consumption, and long life.

LED light tubes can also be used in high-end architectural applications. This is not to be confused with price- sensitive mass lighting. The LED light tubes are meant to provide an elegant ambiance and supplemental lighting.

There is often confusion in what people think they are seeing when first glancing at LED Light Tubes. There are those who think they are simple fluorescent lighting. Others think they are an open beam of light similar to an end-to-end laser. Then there are LED tubes that are simply filled with multiple LEDs across the length of the light.

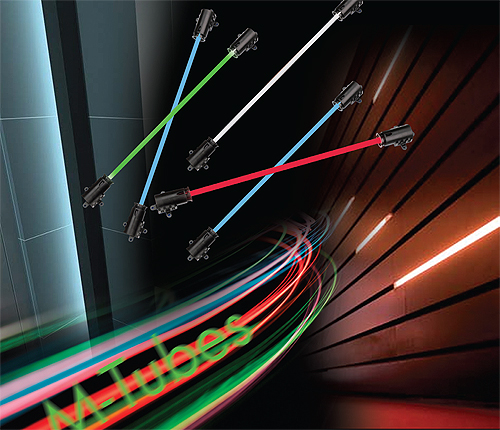

However, a type of LED light tube design generates light from the ends (from one side or both) of the light tube by way of specifically designed housings. The housings terminate the light tube and contain the LED light source as well as provide a means to mount the assembly and provide a heat sink for high brightness versions. The generated light is launched into the ends of a specially designed and imprinted, rugged plastic tubing from one or both of the ends. The tubes can be designed in various standard lengths and diameters. Standard printing on the tube helps to direct the light, and customizations bring a wealth of creative options to light. When a modular design is used for LED light tubes, it enables a wide range of possibilities for various applications in industrial electronics, medical, safety indication, rugged environments, and even high-end mood lighting for ambiance.

In this LED light tube example, the light is driven from each cap on the ends of the tube. They can also be designed with one light end cap source and an end plug on the other side. With one color source on each end cap, different colors from each end can be projected and they blend in the middle.

Launching the Light

The LED light tube can be illuminated by light being generated on both sides with two LED casings or from one side with one LED casing and one empty case on the other side.Launching with two LED casings provides the most homogeneous filling of the tube with light along the entire length of the tube. When very long stretches of tubing is used, adding double-ended light casings along the length of the run helps maintain solid and consistent lighting. Corners and bends are overcome with angled casings, so that the designer is not limited to a straight line. There are also flexible light tubes that can be shaped by the user within reasonable degrees of angles depending on the diameter of the tube used. The light of the LED is passed through the light tube and onto the surroundings with even dispersion that is aided by the axially printed reflector surface.

There are several advantages to LED-based lighting: it is long lasting and boasts very low power consumption, and in our ever energy-conscious world, it is increasingly important to provide lighting solutions that combine these two critical elements. From an aesthetics point-of-view, the colors in the LED tubes can be blended for intriguing results. For example, one LED housing can emit a blue light and the other housing end a red light. In the middle, these two colors blend for a spectrum of purple, while on the ends the two original colors would dominate. Further, the light can be manipulated into various shapes. Using special refractive printing, effects such as “light curtains” can be created. The flexible designs can have light seemingly appear to bend around angles, while still having enough output to illuminate its intended coverage. A very basic form of internal reflection accomplishes this, which is a carry-over from fiber optic principals. The proper treating on internal surfaces can help keep light loss to the outside to a minimum.

High-reliability, rugged applications

For mobile, rugged, or seismic-zone applications, using a lighting system that can survive a harsh environment is very important. In Mil/Aero applications, low power consumption is a key issue. A light tube can provide exact lighting solutions in different colors in a specific shape while maintaining a high degree of reliability and power efficiency. The electronic components, including the LED source, are durable and are resistant against shock and vibration. Light tubes should be made with a hard plastic PC-UL 94 material that is very difficult to break. The environmental conditions can be harsh, and the operating temperature of LED light tubes can be -40°C to +80°C. They also have standard water resistance and most designs are rated to IP 44 for water splash protection.

LED light tubes can also open up a wide range of possibilities in mobile applications. The benefits of resistance to the shock and vibration, high-reliability, and low power consumption can make them ideal for mobile communication consoles, mobile labs, and first responders. Locomotives are one area where vibration is a very real problem for hot incandescent filaments. When the bulbs get hot, they become susceptible to shock/vibration and can break relatively easily.

With various color options using bi-color or tri-color LEDs, and the possibility to modify the brightness and apparent color with Pulse Width Modulation (PWM) drivers, uses in signaling and safety are possible. When attached to an external sensor connected to the LED driver, the light tubes could glow bright red under a warning or danger condition. A change to the input on the sensor (normal condition) could have the color change back to a soft white.

Design for Electronics

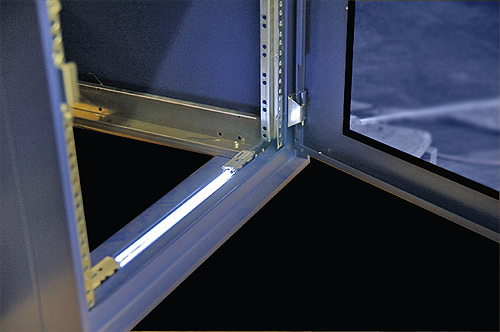

One creative design possibility is to enhance electronics aesthetics and provide supplemental lighting. Consider any front-loaded enclosure with an integrated LED tube below the lip of the chassis. The light could be turned on to enhance the aesthetics of electronics on display, turning a static box into a sleek-looking attention-getting unit. For more everyday use, the light could help illuminate the plug-in boards and provide better lighting when boards or sections are removed. Cabinet enclosures are continually incorporating lighting solutions. A light tube could run along the top, sides or bottom to provide additional lighting and an advanced-design feel.

As the tubes can be placed anywhere and in various sizes/shapes, they can help with illuminated areas such as cable ingress/egress or fan or power areas so that technicians can work faster and more efficiently. Many cabinet enclosures and consoles are used in rugged, seismic, and mobile applications. The rugged design of the light tubes can be ideal for these types of environments.

Color Blending

Elma’s LED light tubes drive the light from each end of the tube, via a housing. This allows the user to have a different color come from each end, providing blends or mix-and-match of colors between each housing segment. This can be used for very creative aesthetic arrangements, for color-coding for electronics or even directional indication, and so forth. The LED tubes are used in some high-end architectural applications for creative designs or mood lighting.

Light tubes can be used inside electronics like this cabinet enclosure to provide low-power illumination in various shapes and lengths. With a rugged and reliable design, the tubes are particularly beneficial in electronicsapplications for railway, seismic zones, military/aerospace, mobile, and more.

High Brightness

Light tubes are typically not brightly lit, but they can be. Often the tubes are used to provide background lighting or even create a decorative ambiance in some applications. However, high brightness versions can be achieved via two high-efficiency ultra-bright LEDs. The high brightness LED produces a luminous flux of 250 lm at a typical operating current of 600 to 1000 mA in continuous operation, as opposed to approximately 150 mA for the standard brightness versions. The high brightness LEDs have a very low specific thermal resistance of 2.5 K/W in the SMT package, enabling the heat produced in the chip can be efficiently removed. The LED has a maximum junction temperature of 175°C, allowing the LED to be used in situations where ideal cooling cannot be achieved. By employing an aluminum heat sink, the design can accomplish additional thermal management of the powerful LEDs and simultaneously serves as a design element and light guide while helping to ruggedize the mounting scheme.

You can see the light quality

Simple, low-cost LED light solutions can be incorporated into electronics available in the market as well as Elma’s high quality offerings. However, these lower cost units display light quality, brightness, and consistency that are not the same as can be generated with high-end designs.

An important consideration for lighting systems is maintaining reliable and consistent color over time. As light-guides age or are exposed to heat, the clear material can begin to turn yellow. This can affect the color that is presented and the overall light intensity. To prevent this, higher quality, heat-resistant materials are an absolute requirement for good optical performance. These same materials can also prevent premature cracking and are necessary to maintain physical integrity. High-grade polycarbonates are ideal for these applications; and with modern, extreme high-pressure injection molding techniques, PC light pipes virtually are free of light dispersing imperfections and will remain more optically transparent over time than other choices of materials.

Discuss this on the Engineering Exchange:

Elma, Inc.

www.elma.com

::Design World::

Filed Under: Lights • signal lamps • indicators, ELECTRONICS • ELECTRICAL

Tell Us What You Think!