Why in the world would anyone need a ball screw with a left-handed thread? Why not simply reverse the program and drive the device in the opposite direction? Unfortunately, this may not always be the best solution. Several industrial applications require a left-handed ball screw to help resolve high-precision programming requirements and reduce the number of needed expensive components.

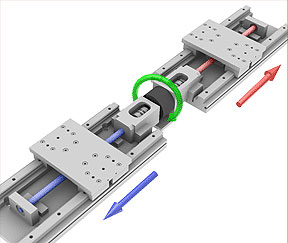

For example, imagine a system designed with two ball screws; one right-handed and the other left-handed, with each unit positioned on either side of one drive motor moving in opposite directions. This configuration is less expensive and much more practical because only one motor is required and there is no need to synchronize two separate right-handed ball screw systems driven with two servo or stepper motors.

Another application comprises two units placed in parallel and connected with a belt drive and two pulleys. This arrangement contains one motor that drives two linear motion mechanisms in opposite directions.

Left-handed ball screws can be made to suit most current applications in machine building, assembly system design, and other factory automation integrations. For example, they may be specified with a reversed-direction flange nut, key grooves or flat ends, unfinished support sides, and grease for cleanroom and food processing applications. In addition, ball screws can be designed for many custom applications and delivered in as little as eight days.

Misumi

www.misumiusa.com

Filed Under: Ballscrews • leadscrews, Machine tools + subtractive manufacturing, Motion control • motor controls

Tell Us What You Think!