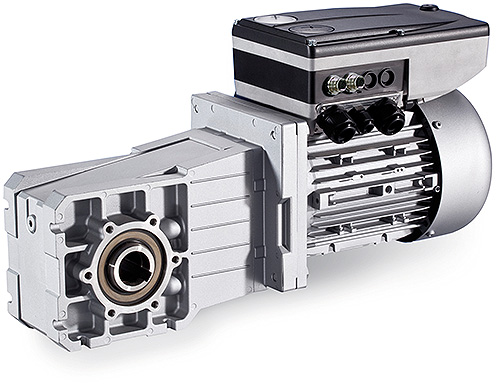

Lenze Americas highlighted two new inverter drives at ProMat 2011. The compact Lenze 8400 Motec and 8400 Protec are decentralized inverter drives equipped for all drive functions and scaled for the needs of the material handling industry.

“For decentralized applications, the 8400 Motec and Protec frequency inverters are a great fit. Steering the whole drive package, the 8400 inverter series is expertly matched with high efficiency Lenze motors, gearboxes and brakes,” notes Darrow Hanesian, Global Director of Inverter Products, Lenze Americas.

Benefits of 8400 Motec and Protec inverter drives include:

— Rugged IP66 enclosure

— Delivered with mains, motor, brake and communications connectors for ease of installation

— Standard communication via PROFIBUS and PROFINET with CANopen as an option

— Yields up to a 30% decrease in energy consumption

— L-force Engineer configuration software for simple commissioning and optimal control

— Replaceable memory module stores parameters for fast replacement and reduced downtime

Modular, space-saving 8400 Motec and Protec inverters can be installed at the point of use, directly on the motor or an adjacent wall. Applications might include winding sheet metal, running blister packs, cartons and end-of-the-line packaging equipment, positioning rotary indexing tables and driving extruders and fillers.

The 8400 products comprise the BaseLine, StateLine, HighLine, TopLine, Motec and Protec lines, complementing a wide range of functionality and specifications. Lenze 8400 inverter drives feature memory modules, online diagnostics and safety systems. Identical installation, parameterization and user operation across the product family simplify the process of outfitting a single production line or designing a full factory installation.

Lenze Americas

www.lenzeamericas.com

::Design World::

Filed Under: Drives (servo) + amplifiers, Material handling • converting, Motion control • motor controls

Tell Us What You Think!