Robots aren’t all humanoid and SCARA; some take the form of linear-motion arrangements. In fact, we’ve covered how Cartesian arrangements in particular offer better energy efficiency and price points than more stereotypical robotic arrangements.

You’ll get copious amount of information on such linear designs and technologies at the 2019 Robotics Summit (on commercial-robotics design, development, manufacture, and delivery) happening in Boston the first week of June.

Bishop Wisecarver • Booth #131 — Chat with the engineers on team BWC for help on manufacturing and automation installations needing linear robotics of all types. The supplier’s HepcoMotion line was specifically introduced to satisfy mechanical handling applications — functioning as 7th-axis systems (sometimes called robotic transfer units or RTUs) for welding and assembly in the automotive industry.

Related post: Designing (seventh-axis) linear motion tracks for robotic positioning

HIWIN • Booth #152 — Much of industry associates HIWIN with its linear-motion slide and actuation offerings — including rolled ballscrews, linear guideways, electric actuators, ballscrew stages, and the like. However, the company also manufactures SCARA robots … as well as the strain-wave gearing that has become so prevalent in today’s robotic designs. We got the chance to take a look at this new HIWIN offering at the recent Automate show in Chicago; you’ll get that chance too at the upcoming Robotic Summit.

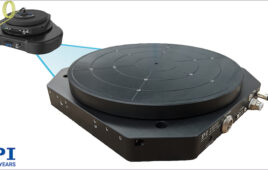

This is the DATORKER robot reducer from HIWIN — a harmonic gearing system.

Lin Engineering • Booth #208 — These friendly folks design and manufacture smooth and accurate stepper motors. During the last 25 years, they’ve reinvented stepper motor technology to address design problems that once had no clear solutions. Other offerings include linear actuators, BLDC motors, drivers, and controllers applicable to robotics.

Festo • Booth #216 — This manufacturer with world headquarters in the Stuttgart, Germany area sells pneumatic and electromechanical systems and controls for all kinds of factory automation. The company makes splashy releases at tradeshows with its bionic robots; read Sensors at heart of bionic robots from Festo from more. However, its linear-motion technologies and end-effecting technologies apply to more straightforward systems for manufacturing.

Macron Dynamics • Booth #105 — This manufacturer with world headquarters in the Philadelphia area focuses on supplying belt-driven linear systems as well as other mechanical motion components and systems. Read our article, Growth industry: Automation in the burgeoning cannabis market and the complementary piece from Macron’s own Michael Giunta, Cannabis cultivation leverages modular automation stations for more information about how Cartesian robots first developed for AS/RS are spurring new designs for indoor farming.

SICK • Booth #144 — SICK is known best for its factory and logistics automation technologies. Here’s a little sampling of what SICK was recently showing at the Promat show in Chicago:

SICK offers the robotics industry technologies for reliable positioning, navigation, measurement, and identification to protect personnel and goods from injuries, damage, and other loss. SICK focuses a lot of its new innovation on technologies that OEMs can use to impart IIoT (Industry 4.0) functionality to machines and systems … leveraging open communication protocols to transmit big data and provide edge computing, among other things.

THK • Booth #115 — LM (linear motion) guides from this supplier work in thousands of robotic systems worldwide. In addition, THK offers other motion technologies for specific applications — including those for medical robots.

Already in Boston or coming early? Free AWS RoboMaker training with Amazon

One last note of something quite cool happening in conjunction with the Robotics Summit: Amazon Web Services (AWS) is holding a RoboMaker Immersion Day on Tuesday June 4th (the day before the Robotics Summit starts) at their Boston location. You can attend this event for free to learn how to use AWS RoboMaker for developing, testing, and deploying intelligent robots.

Filed Under: Warehouse automation, Cannabis, Linear Motion Tips, Motors • stepper, Robotics • robotic grippers • end effectors

Tell Us What You Think!