Gefasoft developed a system for the optical inspection of diffusers for airbags through 11 camera stations requiring varying inspection times. For this application, the company chose the eXtended Transport System (XTS) from

Beckhoff Automation.

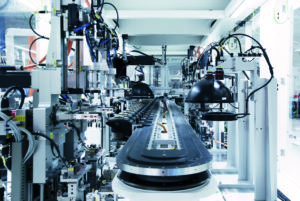

German automation systems supplier Gefasoft recently developed a system for the optical inspection of diffusers for airbags through 11 camera stations requiring varying inspection times. The company chose the eXtended Transport System (XTS) from Beckhoff Automation.

For complex component shapes, optical inspection systems typically require a series of cameras in serial or parallel stations to check all criteria. The Sova-VIS 16 system from Gefasoft Automatisierung und Software GmbH is no exception. Because they are safety-critical components of the car airbags, the cup-shaped, drawn sheet metal parts — produced in various versions with diameters of approximately 60 millimeters — must undergo inspection of their interior and exterior surfaces.

While some inspection tasks require only a single picture, others require sophisticated lighting systems and multiple images. The interior wall of the diffusor is a critical surface that must be inspected for even the smallest imperfections with dimensions of only a few tens of micrometers. Line scan cameras are used before the part is trimmed to achieve the proper image resolution. The trimming process alone takes about 2 seconds, meaning the image acquisition times vary significantly between the individual stations.

As safety-critical links between the airbag and the inflator or gas generator, diffusers must be inspected quickly and efficiently.

If all camera stations were linked through a rigid conveyor system, such as a rotary indexing table, the station with the longest image acquisition time would determine the shortest cycle time of the entire system and limit the throughput rate accordingly. However, with the flexibility of the XTS, faster inspection stations can be served at a higher rate, while slower stations can be supplied with components simultaneously.

“With the Sova-VIS 16 system, the heterogeneous imaging times of the individual steps led us to look for a machine layout with a flexible, asynchronous transport system that would enable us to perform the job efficiently in a limited amount of space,” explains Georg Schlaffer, marketing manager for Gefasoft. “Despite the presence of slower inspection stations, we were able to achieve an average cycle time of 1.9 seconds.”

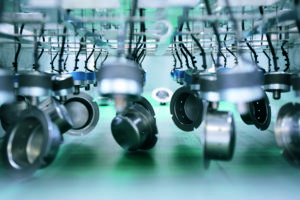

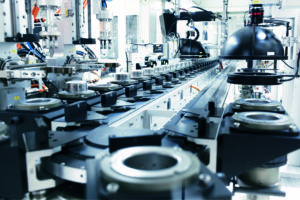

XTS movers with upper and lower mandrels (left and right images) pick up the diffusers in “hat “or “cup “orientation. Also visible is the sprocket used to rotate the parts in front of the line scan camera.

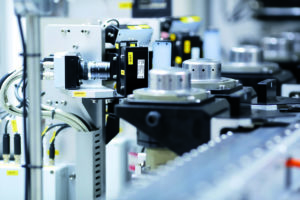

Engineering Director Christian Schärtl explained that because of the demand for these parts, the end customer specified a cycle of less than 2 seconds. Because two of the inspection steps take almost 4 seconds, these stations had to be duplicated and parallelized to meet this goal. “Other solutions with carriers and switches based on belts or chains would have required much more complex mechanics and would have been slower while taking up more space, said Schärtl.”

Because of the many camera inspection stations, the total length of the XTS line amounts to approximately 11 meters (36-ft) with 30 movers. Due to the mover’s weight, the line was equipped with a special guidance system made by HepcoMotion. The mass of about 4 kilograms (8.8 lbs.) per mover was needed to accommodate the handling requirements with units for lifting and rotating — the diffusers must rotate precisely in front of the cameras and be able to move in two layers (“hat” and “cup”) so their top and bottom sides can be inspected.

Positioned in “hat “and “cup “orientation, the diffusers pass through the inspection stations, some of which exist in duplicate versions.

The goal was to use a single inspection machine to fully automate the process, which ranged from picking up the parts from a pallet to stacking or sorting them with a robot. Distributing the inspection tasks over multiple independent machines was not an economical option for the end customer. Besides the complex logistics between the machines and their increased space requirements, it would also have been too expensive to split up the feeding process of the diffusers from bulk containers.

After the surface of the components has been degreased, the diffusers are supplied to the inspection machine as bulkware in mesh pallets. A gripper takes the parts from a conveyor and passes them to the XTS. To ensure proper orientation for the workpiece holder of the XTS mover, the transfer station has a camera that detects the diffusor’s positional angle as well as its type. Each diffuser has a batch number embossed in its top, which is checked in the first camera station.

With the eXtended Transport System, Gefasoft was able to optimize the quality inspection of cylindrical metal parts.

After detecting the batch ID, the system checks the interior of the diffusor, which requires it to be rotated in the mover from a “hat” to a “cup” position — with the opening pointing upward. To do this, the parts are picked up from the mover with a gripper, rotated 180° and placed back onto the mover. Meanwhile, the internal mandrel is withdrawn so that the part is centered and resting on its flange. To inspect the surface of the part’s interior it is then rotated in front of a line scan camera.

“What turned out to be a major challenge was the limited space because the camera and four lights had to fit inside the part, which only has an interior diameter of approximately 60 mm,” Schärtl explains.

“To resolve this, we had to design an integrated lighting and camera unit, which dips into the part while a servomotor docks from the outside to the rotatable mandrel in the mover. Also, a fast controller had to be developed for the lighting system. Moving the lighting unit into the component and rotating it takes a little more than 2 seconds. To achieve the line cycle time of 1.9 seconds, we installed two of these inspection stations.”

To inspect the diffusor interior, parts are removed from the XTS mover and rotated 180°with a gripper to achieve the correct camera angle.

The rotating stations are followed by a control station for material deviations and a station for inspecting the base of the diffuser. The last camera station of the first linear XTS section checks the flange for flaws. This configuration means that the first linear section holds six camera stations. With duplicate line scan and rotating stations, this brings the total to nine positions.

After the movers have passed through the 180°curve of the XTS, more camera stations, as well as a printing station for marking the diffusers, follow on the other side. The parts are flipped from “cup” to “hat” orientation before two parallel line scan camera stations check their exterior surface. This is followed by the inspection of the upper side of the flange, a camera-controlled inkjet printer for marking faulty components that is synchronized with the motion of the XTS movers, and a laser for marking the good parts. At the end of the second linear XTS section, a Stäubli TP80 robot picks up the parts from the mover for further processing.

Beckhoff

www.beckhoff.com/XTS

Filed Under: AUTOMATION