The new Lowe’s 3D printing kiosk. Image credit: Lowe’s Bespoke Designs

How about printing your next home renovation project? Lowe’s has become the latest company to let customers customize items using 3D printing.

Specifically, visitors to the Lowe’s flagship store in Manhattan can check out bespoke 3D printed designs. These are enabled through Digital Forming, a SaaS platform from a London startup.

They advertise the service as perfect for creating replicas of heirlooms or saving significant moments (like bronzed baby shoes.) Broken parts from antique or out-of-production items can also be repaired this way, as long as the original part can be scanned. Because the designs are stored in a personal Bespoke Designs account, these pieces can be replicated, as well as examined more closely: technicians will be available to show how parts have broken down and provide an appropriate 3D model.

Services like this may take a long time to print or be unable to be fixed at a local store. As well as walk-ins, the bespoke print office will also ship parts back to customers.

UPS also offers a print-on-demand service.

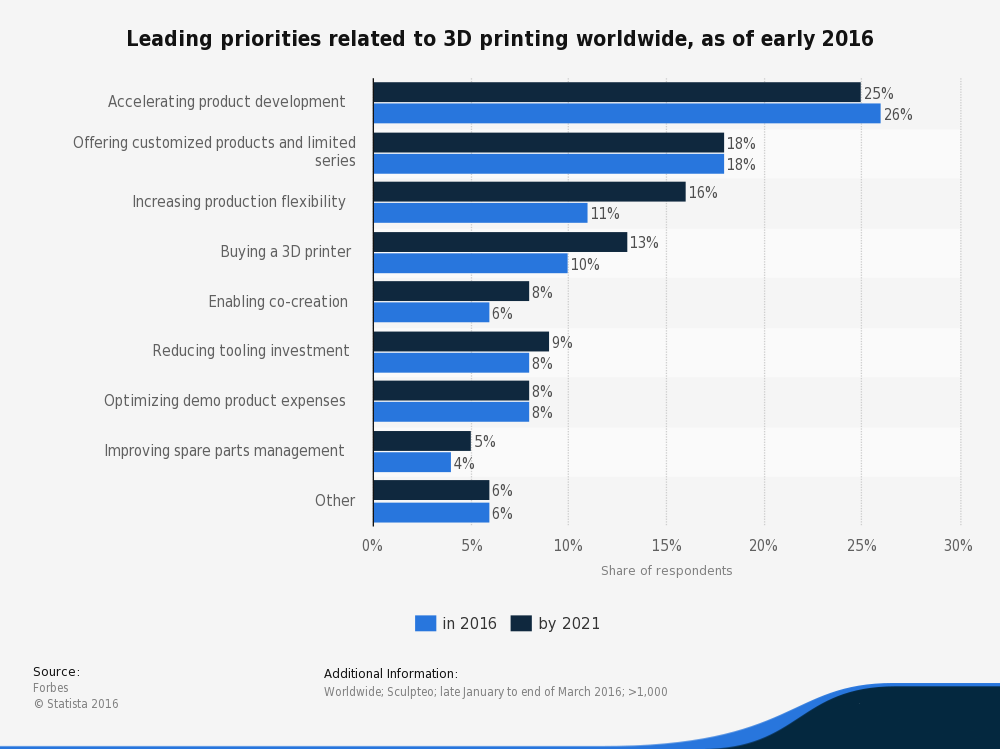

The 3D printing manufacturing business is expected to grow to $17.2 billion by 2020, according to Statista. However, some 3D-printing first companies are struggling a bit – MakerBot shut down its three retail stores in October. A study conducted in early 2016 showed that most people who use 3D printing expect to use it in product development, with 26 percent saying that accelerating product development was their priority in terms of utilizing 3D printing in 2016.

Customized products, such as Lowe’s is offering, came second on the list, with 18 percent of respondents listing it as their first priority.

Filed Under: 3D printing • additive • stereolithography, Rapid prototyping