It is a reasonable assumption that an efficient wind turbine will generate a lot of wind driven electricity. One way to achieve better wind turbine efficiency is with the proper gearbox lubricant. Dow recently introduced the UCON™ GL-320 lubricant. Not only is it suitable for wind turbine gearboxes, it can also be used on other types of gearboxes.

Its high viscosity index addresses the issue of cold weather causing high lubricant viscosity without the need for additional VI improvers. It has a higher heat capacity than hydrocarbon oils, which allows it to move more heat, forestalling a shutdown when turbine output is at the maximum. Plus, the lubricant has better lubricity at ambient conditions so that it has the potential to shift the power versus wind speed curve to the left, leading to greater power output when the production is less then the maximum design output.

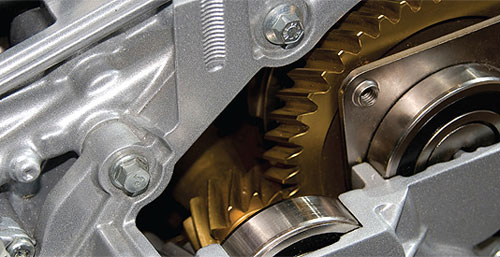

This lubricant also addresses the issue of micropitting, which can lead to wearing and changes in gear teeth shape, reducing gear accuracy, and increasing vibrations and noise. It can also lead to other problems such as misalignment and fatigue failure. High viscosity lubricants like UCON™ GL-320 are a thicker lubricant film that can help to reduce the debris and worn particles that often accompany less well-lubricated gears.

This lubricant is a new polyalkylene glycol (PAG) based lubricant. The combination of the PAG base along with a proprietary Dow additive package yields a ready-to-use product for wind turbine and other gearbox operations.

DOW

www.dow.com

::Design World::

Filed Under: Green engineering • renewable energy • sustainability, Energy management + harvesting, MECHANICAL POWER TRANSMISSION, Gears • gearheads • speed reducers, Motion control • motor controls

Tell Us What You Think!