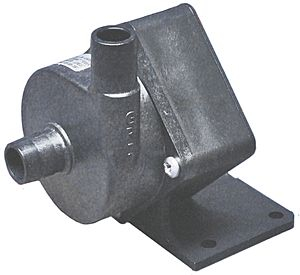

In medical equipment used to recirculate and transfer fluids, leaks must not exist. But seals are not the only way to ensure leak-free operation. A magnetic drive pump offers a different design choice. The Integrity Series magnetic drive pump eliminates motor bearings and leaves the impeller assembly as the only moving part.

Magnetic drive centrifugal pump operation is similar to a standard centrifugal pump except that the motor shaft seal is eliminated. The pumps isolate the wet end of the hydraulic circuit from the motor by driving an impeller and magnet assembly with a radial or axial drive magnet assembly attached to the motor shaft. The drive magnet transmits motor torque through a plastic housing that separates the driven impeller magnet from the pumped fluid. The end result is a more efficient centrifugal pump that will not leak and is capable of achieving up to 50 thousand hours of continuous duty operation.

For the Integrity Series mag-drive pump, the shafts are ceramic with either Teflon® or ceramic thrust bearings. These robust features add tremendously to the chemical compatibility and overall life of the pump to make it virtually maintenance free.

Features:

-NEW integrated, compact design

-Impeller assembly only moving part

-Elimination of motor bearings

-Long life

-Low power consumption

-Quiet operation

-Multiple OEM options

Applications:

-Recirculation and transfer of fluids

-Medical devices

-Automotive & RV

-Chillers & Coolers

-Other OEM markets

GRI Pumps

www.gripumps.com

::Design World::

Filed Under: Hydraulic equipment + components, Pumps, Medical-device manufacture, FLUID POWER

Tell Us What You Think!