Micro-Electro-Mechanical Systems, or MEMS, come in many sizes and configurations; ranging from miniaturized electromechanical chips down to the most unique forms of nanotechnology that sense, measure, transmit, and control virtually every sensing modality. This allows the development of enhanced devices with perception and control capabilities for microsensors and microactuators only dreamed of a decade ago.

MEMS Sensors

One MEMS company is SMART Microsystems Ltd., which specializes in microelectronic assembly with added capabilities of environmental life-testing and failure analysis.

Matt Apanius, managing director of SMART Microsystems, says, “We work on a wide range of products― most of them are sensors and this includes MEMS. We typically work with companies when they need custom assembly for a new product.” He adds, “Our customer companies may not necessarily be in the fortune 500 but they tend to be suppliers to those companies.”

Working with these types of customers, SMART Microsystems has to stay on the leading edge of what’s happening in microelectronic product innovation. “We enjoy working closely with our customers to ensure the incoming material requirements and the processes we develop achieve the design intent and cost objective.”

Another MEMS sensor company is DunAn Sensing LLC, which fabricates MEMS pressure sensing devices. DunAn make the pressure die and then puts them into different packages, according to Gary Winzeler, vice president of sales and marketing,

“We sell directly to big manufacturers of HVAC equipment; refrigerant equipment, freezers, anything that uses a refrigeration cycle,” says Winzler. “Even electric car manufacturers are using refrigerant to cool their batteries. It’s a big market, and it’s growing.”

The growth of the MEMS market has been tracked for over 35 years by Roger H. Grace, president of Roger Grace Associates. Grace, whose firm provides a variety of marketing and consulting services for clients in MEMS and other advanced packaging arenas, has an objective finger on the pulse of sensors and the electronics industry, specifically the device development and manufacturing areas.

“The research that we conduct helps our clients to better understand the potential landmines that need to be circumvented to successfully proceed into any new technological and product development areas; everything from product planning to roll out and all in-between,” says Grace. “We help clients determine what their product needs to do, what to put into it to allow it to do those things, and if applicable, even what it should look like. To make a product, you first need to put together all the electronic functions and define the best sensor for the job.”

Technology Challenges

“Packaging, testing, and the manufacturing method are all highly dictated by the application for MEMS devices,” says SMART Microsystems’ Matt Apanius. “The better the resolution, translates to a big die with many interconnects. A die with a large, pixelated array is challenging for many reasons. Common packaging issues, such as mechanical stress and thermal isolation, become more difficult to manage. Plus, the cost of the die itself is going to be high which makes assembly yield that much more critical.”

“Processing on both sides of the wafer has been a part of MEMS technology since its inception. Within the last decade or so, the IC industry has adopted through-silicon-via technology to support dense interconnects. Despite both of these significant developments, the interconnect of choice that our customers have come to rely upon is wire bonding― almost everything we do involves wire bonding.”

DunAn’s Gary Winzeler says the marketplace DunAn decided to go after first includes measuring refrigeration pressures, heat pumps, HVAC systems, and any industry using HVAC systems and devices.

“If you look at a standard MEMS device, in order to interface in areas of high corrosion and harsh media, they currently protect the MEMS with a stainless-steel diaphragm and then insert an oil fill between the two. That’s costly and time consuming. You have extra machined parts, and the oil filling, which is expensive, actually takes away from the accuracy and repeatability of the MEMS themselves,” he explains. “We stepped back and came up with a way to mount the chip onto a ceramic and connect that up-via packaging with no other protection needed around it. The next step is a product we are just releasing now, where we have removed the O-ring to make it even more robust.”

While starting off targeting that market, DunAn Sensing is also looking at a range of applications: pump manufacturers, valve manufacturers, compressor manufacturers, and gas compressors. Winzeler says there is a whole range of things that can benefit from this product.

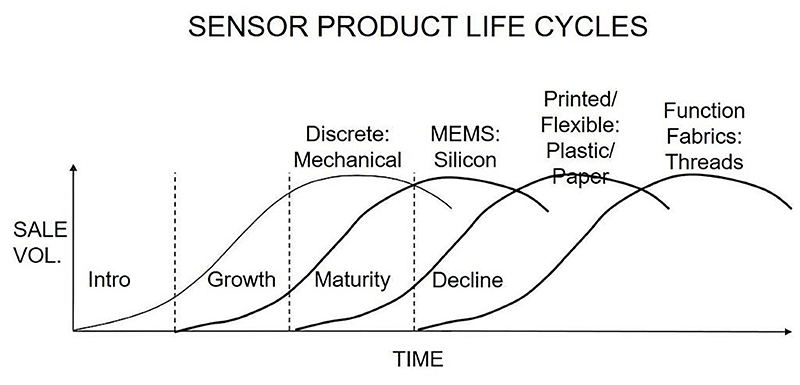

Industry consultant Grace reminds all developers and end users that there are several possible platforms in which the sensor can be created, including silicon, paper, plastic, and functional fabric. The functionality, specifications, features, and the resulting pros and cons of each must be weighed for each application. A knowledge of the myriad types of sensors and their technologies needs to be in every electronic engineer’s mental design toolbox.

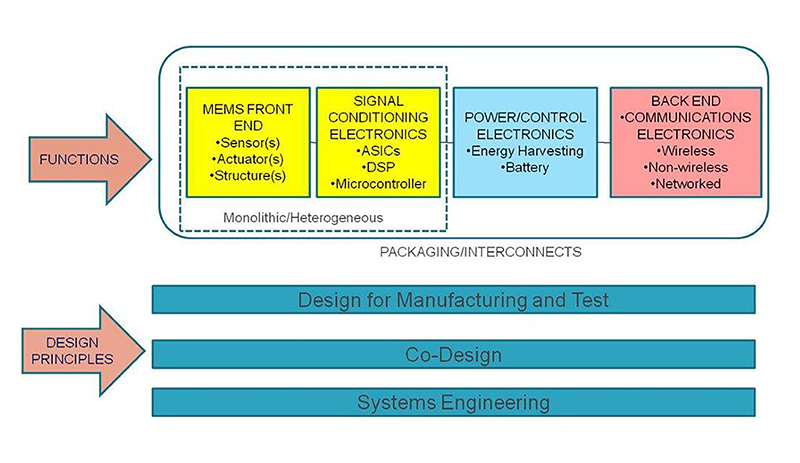

“Current and future successful products embrace the concept of packaging and integration. This packaging concept has to come in at the very beginning of the product development cycle. It is the systems approach to the solution (Figure 1),” says Grace. “Everyone involved must get together early in the process, and create a system with all the design issues and problems flushed out in a first meeting. Great designs can be developed in a CAD system, but when it comes to the reality of manufacturing, they find it can’t be done, and it’s back to the drawing board—which is why so many new devices are so expensive and some never even make it,” he adds. “The device must be able to survive the environment in which it is immersed, do its job, be inexpensive, and still make a profit. To me that’s the real challenge of all of this—to interconnect, test, and package it.”

Figure 1: Designers must consider a systems design approach when selecting a sensor, especially the interfacing circuitry typically realized by an Application Specific Integrated Circuit. (Image Source: Roger Grace Associates)

SMART Microsystems’ Apanius believes that miniaturization solutions based on microelectronic assembly will continue to drive the market. “That’s the strategy for SMART Microsystems. The system integrators and manufacturers in our backyard, such as Parker Hannifin, Eaton, Rockwell Automation, Nestle, etc. are all are thinking the same thing: How do I get more bang for my buck? They are looking at data-based system solutions that rely on sensors and electronics,” says Apanius. “That’s where we come in. We service the custom runs for all major industries. We are seeing some exceptional growth right now with several new programs maturing nicely, and we are very excited about that!”

DunAn’s Winzeler says that DunAn is coming out with a new range of products that use a revolutionary way of interfacing the MEMS to the media. “We are doing it to get a very low-cost packaging method while still maintaining all the high reliability, along with affordability. We have also come up with a device that combines a temperature sensor with a pressure sensor in the same MEMS package,” says Winzeler. “In the HVAC area, specifically in the area of refrigeration, they typically want to measure pressure as well as the temperature of the refrigerant. Then, they calculate the super heat which is used to control the use of various fans, compressors, and controls within the systems.”

Winzler adds, “In order to obtain the efficiency needed today, it’s truly critical that they control all the parameters, and they want to do this all at the same measurement point. So, we’ve combined all the technology needed and given them a dual output device that gives them a single point to measure all parameters. In our O-ring-less MEMS package (Figure 2) , we are going to be banking that with hard banding, and over-molding the package into a single device will be very robust and have an excellent environmental interface as well. It will be able to be submerged in water, withstand severe humidity and vibration. It will have more structural and environmental protection than any other device on the market right now.”

Figure 2: Overmolded package for environmental protection. (Image Source: DunAn Sensing)

The best advice Winzeler has for any company developing any technology for the future is to go out and talk to customers. “You have to find the real-life problems and then come back and develop the solution. Many companies are getting so big they tend to lose that one-on-one with customers. If the company can solve a customer’s problem, it doesn’t matter how big or small the company is. It just matters that they took the time to get the solution to the customer. With MEMS in the area of pressure and temperature sensing, it has definitely been changing and growing in the area of corrosive media or changes in packaging. It’s all about focusing on customer needs, Winzeler says.

Grace believes the future lies in the market for sensors that can measure psychological chemical/biological phenomena, including blood, sweat, and tears. The measurement of these and other psychological phenomena can be used to determine important changes in physical condition, such as dehydration in athletes or the elderly. Given these requirements, technologies such as silicon MEMs are maturing and will eventually decline, while printed/flexible technologies are on the rise (Figure 3).

Figure 3: According to the four waves of innovation, technologies such as silicon MEMs are maturing and will eventually decline, while printed/flexible technologies are on the rise. (Image Source: Roger Grace Associates)

Filed Under: Sensors (pressure), Product design