Mentor Graphics Corporation (NASDAQ: MENT) announce the newest version of its FloTHERM® product. The FloTHERM product was developed to quickly identify potential thermal issues early in the design process to avoid expensive late stage re-design and warranty costs arising from thermal failures in the field. The newest version of the FloTHERM product delivers an automated method to calibrate simulation models to match transient thermal measurements recorded with the Mentor Graphics® T3Ster® hardware. As a result, the FloTHERM product can help maximize simulation data accuracy and provide additional insight into product reliability – a necessity for the automotive, aerospace and electronics products industries.

Mentor Graphics T3Ster product is an advanced thermal tester for thermal characterization of IC packages, LEDs and systems which produces extensive thermal characteristics rapidly. The industry-leading T3Ster test system delivers highly accurate, real-time measurements of heating and cooling transients based on its advanced implementation of the JEDEC static test method (JESD51-1) and can now be considered to be 10X better than alternative solutions.

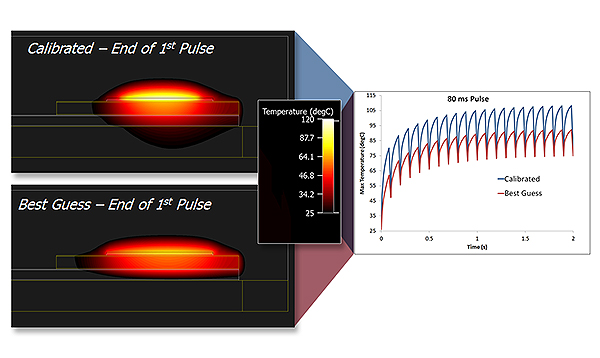

The new FloTHERM product can convert a simulated transient thermal response into a structure function curve using the same mathematical process utilized by the T3Ster product. These structure function curves are known to correlate with the physical structure of the device, and are thus the ideal platform to compare simulation with test data. Differences between the structure functions indicate that some aspect of the simulation model is incorrect; typically dimensions or physical properties that are difficult to measure directly such as thermal interface material (TIM) thicknesses or interfacial thermal contact resistances. The new FloTHERM version uses optimization methods to change the model inputs and drive the simulation structure function towards the experimental structure function until a match is achieved. This match indicates that the FloTHERM model is fully calibrated and will respond correctly and accurately in any transient application. Package manufacturers can now certify supply chain models, by providing evidence about the thermal performance of the component in customer applications along with the model itself.

Additional features in the new FloTHERM product include:

• Joule heating – DC electrical calculations are now supported for joule heating effects to be accurately predicted, enabling power distribution net analysis and bus bar design to be performed.

• FloMCAD Bridge enhancement – 64-bit support enables larger MCAD designs to be imported into the FloTHERM product. In addition, the voxelization method used to translate MCAD geometry into analysis objects was re-engineered to be 20 times faster and much smarter, ensuring that coincident faces on different bodies maintain that connection after translation.

• Localized grid spaces – overlapping localized spaces can now be created. The FloTHERM product makes it easy to construct an efficient grid for large cluttered geometry because the arrangement of localized grid spaces is no longer a concern.

• DCIM Software Development Kit – The kit includes everything a DCIM supplier needs to drive FloTHERM, capture the simulation results, and display them within their DCIM software suite. “Mentor Graphics’ DCIM Software Development Kit provides all the hooks DCIM firms like us need to integrate FloTHERM with software such as FieldView 2015™ with ease. This enables us to drive FloTHERM from within our software suite and display the results, including the way shown in the Excel-based example” added Dr. Fredrick Dirla, Jr, CEO of Fieldview Solutions. “I applaud Mentor for democratizing CFD for data center simulation and eliminating guess-work.”

Mentor Graphics Corporation

www.mentor.com/products/mechanical/flotherm/

![]()

Filed Under: 3D CAD World