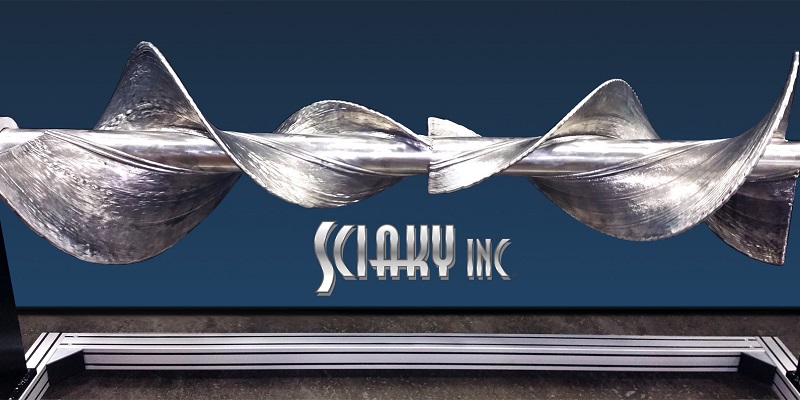

A large titanium screw created using Sciaky’s Electron Beam Additive Manufacturing. (Phillips Service Industries)

Metal 3D printing solution provider Sciaky’s newest Electron Beam Additive Manufacturing (EBAM) systems and other additive manufacturing services will be on display at the International Astronautical Conference.

C.M.I. Electronic Industries Trading will represent Sciaky at the event, which takes place Oct. 12-16 in Jerusalem.

Read more: Top Five Reasons to Integrate 3D Printing Into Your Product Development Lifecycle

The update to the EBAM metal additive manufacturing system includes more options for part applications of medium, large, and extra-large sizes. Philips Services Industries, which Sciaky is a subsidiary of, claims that EBAM is the most scalable metal additive manufacturing option (in terms of work envelope) for parts between 8 inches and 19 feet in length. Philips also asserts that EBAM’s gross deposition rates of between 7 to 20 pounds of metal per hour make it the fastest deposition process in its market.

EBAM functions using wire feedstock, which can be found in a variety of materials like titanium, tungsten, aluminum, stainless steels, and nickel alloys. The dual wirefeed system allows EBAM users to mix two metal alloys into a melt pool for the purpose of creating custom alloy parts or ingots. The mixture ration of the two materials can be altered to developed graded parts or structures. To achieve finer deposition features (thin wire) or gross deposition features (thick wire), users move between differing wire gauges.

“Our new EBAM systems and flexible Additive Manufacturing services provide manufacturers a variety of options to save significant time and money on the production of metal parts and prototypes,” said Sciaky General Manager Mike Riesen.

Filed Under: Industrial automation