Thursday, October 1, 2020

2 Pm ET / 11 AM PT

Today’s manufacturing industry requires small & precision parts with high performance and reliability at a competitive cost. This 45-minute Webinar discusses a unique process that eliminates the need for complex, expensive machining when producing small, intricate steel and stainless steel components for automotive, Industrial and consumer product applications. The process is metal injection molding – also known as MIM. The presentation also examines how switching to the MIM process can result in a minimum 30% cost reduction for specific applications.

Today’s manufacturing industry requires small & precision parts with high performance and reliability at a competitive cost. This 45-minute Webinar discusses a unique process that eliminates the need for complex, expensive machining when producing small, intricate steel and stainless steel components for automotive, Industrial and consumer product applications. The process is metal injection molding – also known as MIM. The presentation also examines how switching to the MIM process can result in a minimum 30% cost reduction for specific applications.

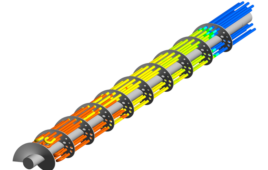

In the MIM process, a very fine metal powder is mixed with a little plastic, and then the mix is injection molded into complex shapes utilizing a mold. The molded components go through a de-binding process, during which some of the plastic binder is removed, and then they are sintered at high temperatures. During sintering, the remainder of the plastic binder is eliminated, and the metal particles diffuse with each other to form 96-98% dense material without losing its shape integrity.

The sintered MIM components display strength characteristics comparable to machined components. The process is highly scalable, and the material options include all varieties of steels, stainless steels, titanium, nickel super alloys, tungsten alloys, tool steels.

Attendees of this webinar will learn about:

- Overview of MIM Process and its application

- Cost saving ideas, advantages and limitations

- Design guidelines and material selection

Featured Speakers:

Jag Holla

Jag Holla

Sr. VP- Marketing Group

INDO-MIM

Param Gutti

Param Gutti

Sr. Manager- Business Development

INDO-MIM

Leslie Langnau

Managing Editor, Moderator

Design World

Sponsored by:

Filed Under: Molding • injection molding components, WEBINARS