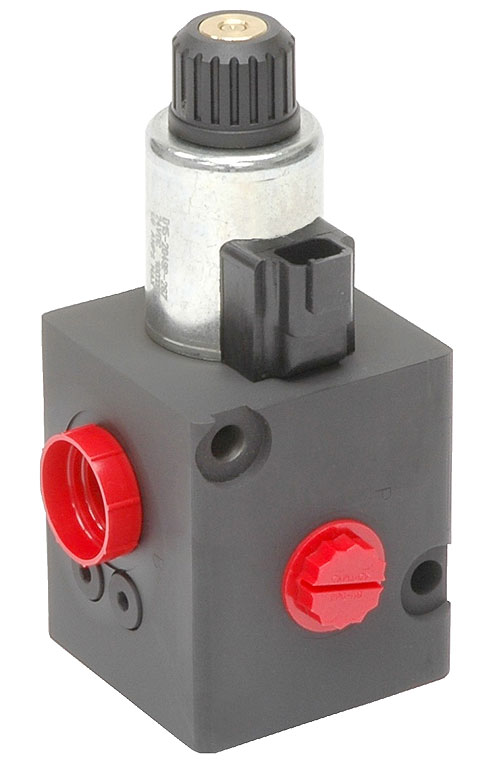

NORTH MANKATO, MN —The S12 Series Electrohydraulic Brake Valve (EBV) from MICO, Incorporated provides more than triple the flow capacity of a traditional EBV. In large, spring-applied, hydraulic release brake applications, it has been able to replace two standard electrohydraulic brake valves operating in parallel or an EBV and relay valve. This lowers cost and improves system reliability.

The S12 series uses the MICO patented auto-relieving feature to get more travel and flow capacity out of the proportional solenoid valve. The brake valve reliably handles high flows without the complexity and orifices associated with pilot-operated fluid power valves. Instead of using a pilot valve, with its associated high leakage and contamination sensitivity, a high force solenoid is combined with a precision fit spool and housing to maximize contaminant resistance and minimize leakage.

The successful cross-hole metering set-up of the standard MICO electrohydraulic brake valve also is used in the S12 Series EBV. The S12 incorporates a longer spool to incorporate a second flow path — which runs parallel to the standard path — giving the new series a higher flow capacity from brake to tank. These features make the valve ideal for spring-applied, hydraulic release brake applications requiring high flows such as those found on vehicles with large displacement brakes.

All MICO EBVs are developed specifically for full power brake systems. These applications require rapid and controllable filling, or emptying, of single-acting actuators, and modulating pressure without consuming significant pilot flow from the accumulators used to store energy during “power-off” braking.

The S12 series rounds out a complete line of MICO EBVs — handling larger systems than previous EBV designs. The EBV-M is prevalent in hydraulic-applied, spring-release brake applications; the EBV-S works with spring-applied, hydraulically released brakes; and the EBV-A is used to add ABS to full-power brake systems.

MICO, Incorporated

www.mico.com

::Design World::

Filed Under: Hydraulic equipment + components, Automotive, Valves, FLUID POWER, Off highway • construction • agriculture

Tell Us What You Think!