By Jay McKenna, Global Product Manager New Products, PennEngineering, Danboro, Penn

As electronic devices continue to miniaturize, the fasteners required to assemble them are becoming smaller as well.

Extremely small micro fasteners have made significant inroads in the global marketplace especially with the ongoing evolution of smaller, lighter, and thinner consumer electronic devices. Traditional threaded micro screws were among the first types that fit well in such applications characterized by restrictive design envelopes and limited footprints for fastener placement and installation. Yet, small screws remain a viable option today in many applications.

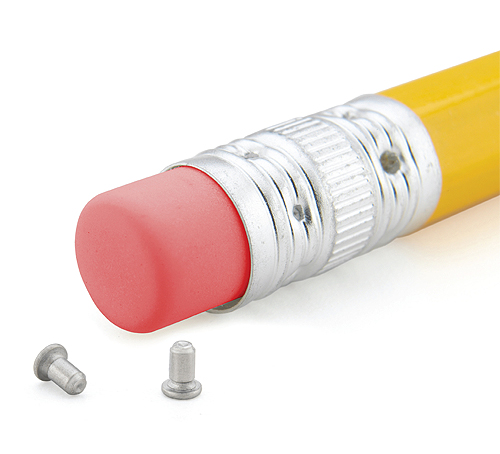

PEM micro locating pins are used in cell phones, hand-held devices, computers, and electronic games.

The bigger story is that micro screws marked only the beginning of micro fastener technology. Most notably, self-clinching micro fasteners (some threaded and some not) offer more choices to designers. These clinch fasteners install permanently where designed, minimize the need for additional hardware, and can streamline the production process especially when installed automatically.

Regardless of size, all self-clinching fasteners become permanently retained in thin metal sheets through a displacer and an undercut in their design. When the fastener is pressed into a properly sized hole, metal from around the hole is forced by the displacer to flow into the undercut around the circumference of the part beneath the fastener’s head. The fastener is then securely locked in place and will not loosen or fall out.

For micro clinch fasteners, precision engineering and manufacture have become vital to success because these fasteners are not simply scaled-down versions of their larger self-clinching counterparts. As fasteners are “downsized,” issues relating to tight tolerances and performance values are magnified. Specialty design and unique features must be engineered to meet specifications.

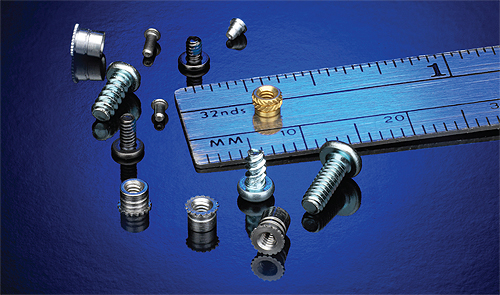

There are several micro self-clinching fasteners and other non-clinching options that can be used for a variety of applications as noted below.

Threaded self-clinching micro standoffs

This type of fastener is well suited for space components. Standard types have threads as small as M1.0/#0-80 and in lengths as short as 2.0 mm/0.080-in. Those made from 400 Series stainless steel can be installed into sheet metal (including 300 Series stainless steel) as thin as 0.4 mm/0.016-in. with maximum hardness up to HRB 88 on the Rockwell “B” scale. Applications requiring installation in sheets as thin as 0.2 mm can be accommodated with specially engineered standoff designs.

Unthreaded self-clinching micro locating pins

These types ideally suit locating or positioning applications. Standard types are manufactured from age-hardened A286 stainless steel and designed with diameters as small as 1.0 mm/0.040-in. and in lengths as short as 2.0 mm/0.080-in. They can install permanently into stainless steel or other sheet materials as thin as 0.5 mm/0.020-in. with hardness up to HRB 90 on the Rockwell “B” scale.

Self-clinching micro tack pins

These fasteners with diameters as small as 1.0 mm can permanently attach two panels for applications where an alternative to screws, welds, rivets, or adhesives is preferred.

In addition to typical displacer and undercut, tack pins incorporate a tapered point and tangential interference band that work together to guide the part into the small-diameter and shallow hole in the panel and create a slight interference fit between the hole and the fastener at the interference band. This phenomenon creates minimal stresses in the host sheet (which can be as thin as 0.77 mm) and absorbs any tolerance between the diameter of the hole and the diameter of the clinching pin.

Surface mount micro fasteners

These fasteners will eliminate the need to manually place hardware on a populated printed circuit board. Surface mount micro hardware supplied on tape and reel can be positioned while a board is being processed and then installed with the other electronic components using conventional surface mounting equipment. Quality issues related to board cracking and misalignment will disappear since the hardware installs automatically with the same pick-and-place robotic equipment used for a board’s electronic components. The process is non-intrusive to the board and will not expose a board to cracking. Since the fasteners are packaged on tape and reel, different parts will not inadvertently get mixed.

Threaded micro inserts

These brass or stainless micro inserts provide strong and reusable metal threads to attach plastic assemblies. Thread sizes can be as small as M1.0.

There will be more micro fastener innovations. In our case, a steady supply of new micro fastener products has compelled us to engineer the all-inclusive microPEM brand family of fasteners that include self-clinching types and micro screws. New products like these will increase in response to customer challenges and needs. A promising trend is a growing partnership between OEM designers and fastener manufacturers to develop the most practical solution for any application.

Discuss this on the Engineering Exchange:

PennEngineering

www.pemnet.com

Filed Under: FASTENING • JOINING • locks • latches • pins, ELECTRONICS • ELECTRICAL

Tell Us What You Think!