Mitsubishi Electric Automation, Inc. now offers a new IoT Gateway — a network technology that connects machine assets to Cloud services or on-premises servers for remote monitoring and visualization. The IoT Gateway helps organizations meet business objectives and revenue goals by providing access to production information to reveal operational insights and gain business intelligence, allowing OEMs to more optimize machine design, and help end users drive down production costs.

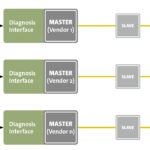

The IoT Gateway is an adaptable solution that provides connectivity to nearly all devices and enterprise systems in the marketplace, as well as up to five programmable logic controllers (PLCs) at a time.

Applications include the management of consumable materials, machine remote services, contextualized visualization, predictive maintenance, and cellular connectivity to remote machines. OEMs in the packaging and printing industries can directly benefit from the insights gained through this access to production information and can aid them in the development of features on their next generation machines.

“The IoT Gateway is the most flexible solution on the marketplace because it can be configured around existing systems across a global enterprise,” said Agnieszka Zupancic, product manager at Mitsubishi Electric Automation, Inc.

“It also lets engineers configure the dashboard, whereas other options may dictate the layout and data that is monitored. This lets OEMs optimize the machine design … in turn helping end users to drive down production costs and take advantage of the Machine as a Service (MaaS) business model.”

For more information about the IoT Gateway, visit this deep link on us.mitsubishielectric.com.

You may also like:

Filed Under: IoT • IIoT • Internet of things • Industry 4.0, NEWS • PROFILES • EDITORIALS, MORE INDUSTRIES