Updated June 2022

Managing motion trajectories is a computing challenge. Just to crunch the numbers and resolve the mechanical organization of a robot into individual axes of motion consumes a good bit of electronics processing power. But assume the move profiles are processed before a move is initiated. That task by itself pales in comparison to monitoring the individual axes on the fly … and executing following-window errors on all axes (so mechanical errors will bring the robot to a halt).

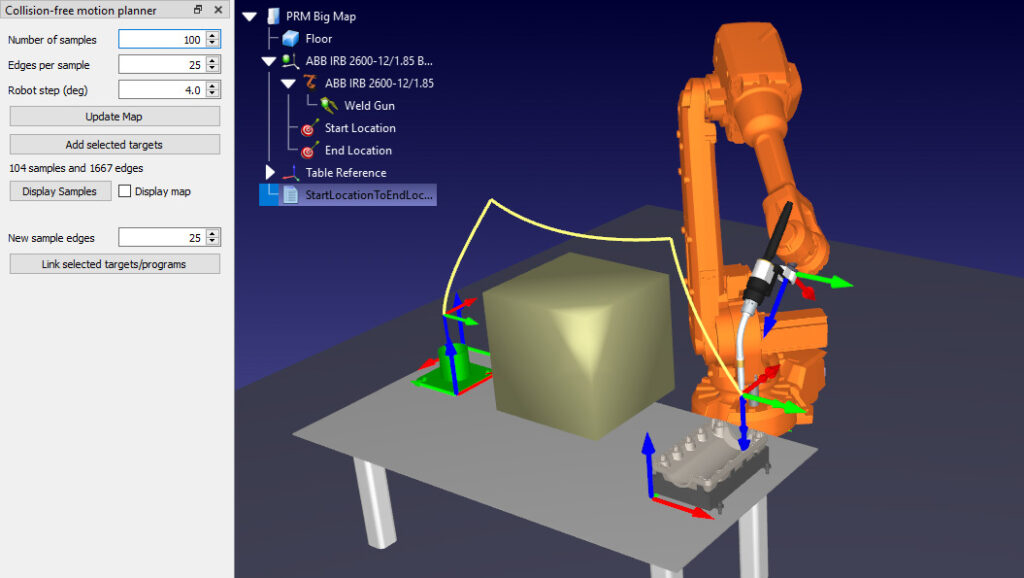

Image courtesy RoboDK

Then when the robot is halted, what exactly constitutes a safe condition? Is that a hold position? A return to home at low speed? All these definitions must be well defined before a robotics system can be put into operation.

See how Realtime Robotics simplifies motion planning at this article on rtr.ai.

Mechanical and installation considerations

Achieving high motion accuracy in a linear or Cartesian system is hard enough. It’s even more difficult for five, six, and seven-axis robots. After all, these aren’t like numerically controlled machine tools having all axes on solid tooling (and reference points and operation geometry that are relatively simple even for complex interactions). Five, six, and seven-axis robots can exhibit significant tolerance stackup. Extra design effort is required on the mechanical integration of the robot itself to minimize tolerance stackup. Use of precision strain-wave gearing or cycloidal gear reducers with high reduction ratios and low mass are two common solutions to this issue.

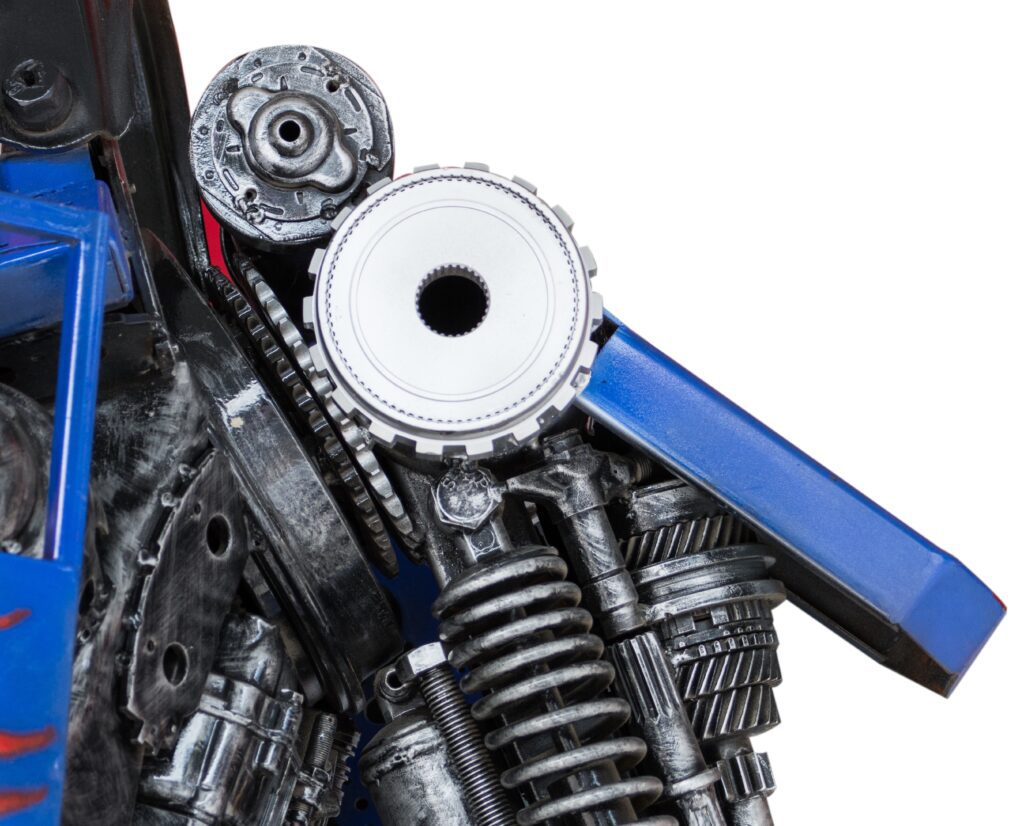

Shown here is a variety of HIWIN Datorker strain-wave robot reducers.

Force feedback from any of the individual axes is handled via a torque (current) motion-control loop between the individual axis amplifier and motor. One pertinent question is how much power is needed. This value depends on how fast the robot needs to go. The amount of force needed includes that to overcome the mass of the actuators themselves as well as the force needed to move the load. This becomes a huge concern when human interaction with robots occur. Robots mustn’t exert forces or speeds that could injure personnel. In some cases, human operators must able to overcome the robot’s actuator system. On these robots, lightweight systems must be designed with highly dynamic controllers.

Compliance is often a key design feature of cobots.

Because of the unique nature of robot controllers, integration with other controls is often difficult. Legacy robot controllers required standalone operation due to the critical nature of the how they operate. Now new offerings make robot integration with other control systems via I/O handshaking or high speed communications easier than ever — but these systems must be foolproof.

The final integration of a robot into the plant or other operating setting is an inherently custom solution — whether a robot is destined for the DARPA Autonomous Vehicle Challenge or a common factory floor. Vision systems may also be required to let the robot find and identify the orientation of workpieces … and in fact, the speed and intelligence of vision systems is often key to the success of the application. ⚙️ Mechatronic Tips

Filed Under: Actuators, LINEAR MOTION, Robotics • robotic grippers • end effectors, Mechatronic Tips