Quick response to catastrophes such as floods and fires is critical, but disaster sites are often inaccessible and unsafe for inspectors and adjusters who come after first responders. Now Pictometry, an EagleView company, collects and supplies ultra-clear aerial photography to let insurance carriers, restoration companies, utilities, and contractors identify safe-access points, areas of total loss, and places where support can provide the most help.

Pictometry has more than 100 surveying planes in its fleet. Cameras on the planes take photos from the north, south, east, and west to build 360° views of properties and parcels.

Nonemergency applications include property assessments and infrastructure planning, as well as authoritative mapping with Pictometry’s AccuPLUS system — fully qualified by the United States Geological Survey (USGS).

A fleet of 100 Pictometry planes sporting USGS-certified camera systems mounted on plane sides, fore, aft, and straight down capture what the company calls Intelligent Images. These images go through processing and then online. Advanced photography methods and motion control are part of the design.

Orthogonal imagery provides top-down views rectified to align to map grids. It also integrates into GIS data for a comprehensive understanding of buildings and local topography. A web-based CONNECT platform (loaded with tools for evaluation, analysis, and measurement) makes it easy for users to view and analyze information.

Pictometry planes fly year-round to continually take images from low altitudes (and avoid atmospheric degradation). The planes’ camera arrays take shots at oblique angles — never parallel or at a right angle to implied lines, but slanting, acute, and obtuse. Those perspectives yield ground images that are more natural (to make objects easier to recognize). Then proprietary processing combines the images into ultra-precise virtual landscapes.

Five cameras use 50 to 350-mm lenses to take photographs together. LiDAR mapping lets Pictometry planes rapidly collect datasets for full-terrain maps. Otherwise, Pictometry planes can use IR and other bands of imaging.

For motion control, Pictometry’s aerial image-capture gear — and fixtures that focus various lenses — use motion controllers from AllMotion. Each airplane has five or more cameras, and run off an AllMotion EZSV10.

More than 600 such cameras are currently in operation.

To capture a scene, all of a plane’s cameras must take their shots in less than a second, even while the plane flies at 100 knots — conditions that make details and available light change swiftly.

The EZSV10s control the cameras’ aperture for metering light

More specifically, the controllers couple to motors that move the gear for an iris mechanism, which makes constant adjustments during flight.

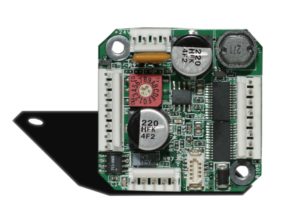

EZSV10 servomotor controllers from AllMotion have onboard EEPROM for storing user programs and can operate as standalone devices.

The AllMotion EZSV10 is an intelligent controller that’s only 0.95 x 1.4 in. and needs little to no tuning when used with most motors 1.5-in. in diameter or smaller.

On the image-capture gear, a single four-wire bus (two power and two communications wires) connects the controller to 16 dc motors in a daisychain to issue commands.

Setup is easy through any serial terminal program or from AllMotion’s EZServo/Stepper Windows application.

The 1.5-A continuous dc brush-motor driver runs off 12 to 40 V. The EZSV10 also has onboard EEPROM for storing user programs and can operate as standalone devices.

This CAD drawing shows how AllMotion EZSV10 controllers mount inside Pictometry imaging assemblies. The controller allows fully programmable motion ramps and speeds, encoder-based feedback, 4-MHz maximum encoder frequency, and PWM or On/Off output.

In addition to the servocontroller, a single AllMotion EZHR17EN controls a gimbal for all five cameras

AllMotion’s EZHR17EN stepper motor controller controls a gimbal to steady the camera array on Pictometry planes.

The gimbal compensates for up to 30° of yaw for each side (or 60° total) and moves whenever the plane is crabbing — moving sideways due to wind. This also helps the cameras stay stable during plane maneuvering.

The AllMotion EZHR17EN is a combination stepper control and driver that (just like the servo controllers) features a four-wire bus and can daisychain up to 16 motors to provide an intuitive command structure.

The controllers also have a selectable step resolution from 1/2 to 1/256 step and the ability to command up to 20 million microsteps per second; they’re also prewired for OptoSwitch inputs.

According to Pictometry, the company chose AllMotion parts for their ease of installation, programming, and maintenance — and because the controllers work right out of the box.

Story provided by Terry Persun, Technology Journalist. For more information on AllMotion servomotor controls in the Pictometry setup, visit allmotion.com.

Filed Under: Motion control • motor controls, Motion Control Tips