By Design World Online

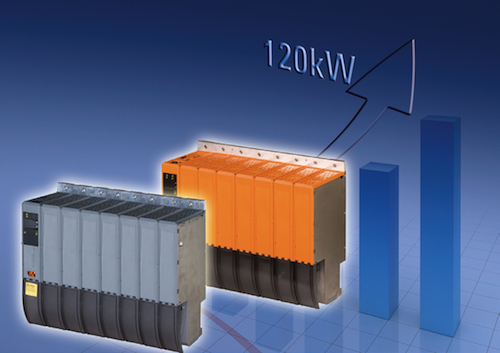

It’s not uncommon today to see servomotors with the drive electronics onboard in low power configurations. Benefits include small cabinet size, simple wiring and support for modular design concepts. But what about applications where a linear motor or a torque motor or a stainless steel motor is required? Or where more power or speed is needed than heat-sensitive motor-mounted electronics can handle? A category of IP65 rated, distributed drive, the ACOPOSmulti65 series, mounts directly to the machine in a convenient location and connects to standard catalog motors.

This approach preserves the benefits of integrated motor drives. It also adds a more practical performance range, onboard distributed I/O handling, and the freedom to use the right motor and feedback for any application. These drives remove the mounting space constraints and heat dissipation requirements of onboard drives. And in some tight machine configurations they can remove the cable strain limitations of a star cabling topology.

The design allows daisy chaining with no special ordering of motors by power rating. And they can be used in combination with a choice of active or passive power supplies as well as conventional multiaxis motors and drives in the ACOPOS family.

The result is added design flexibility. For example, machine modules can be designed with no electrical cabinet, only IP 65 sealed motor modules and connections boxes mounted directly to the frame. The infeed or outfeed or other module is connected to the main machine control cabinet with a single snap-fit cable. Additional I/O on the module, including format change steppers, can be connected and powered by IP 65 remote I/O blocks through the motor modules.

The corresponding control software modules for each machine module are written once and work with high end, mid-range and low-cost controllers. And, machines can be built to meet all the OMAC Packaging Guidelines, including PackML.

This design philosophy fits many current trends in packaging. These include automated conveyor rail adjustments; temporary integration of OEE data collection or high-speed camera modules to analyze machine performance; easy line reconfiguration from feed screws for case packing bottles; to smart belts for collating packs, to stackers and banders for creating multipacks inline.

The IP65 drives suit rotary servo machines because the power and communications in and out of the module requires a bare minimum of slip rings. Whether monobloc or individual machines, it is possible for a single controller and control program to tightly synchronize filling, closure fitment, labeling, along with ancillary systems such as re-torquing, coding, leak and level detection, checkweighing, metal detection, and vision systems for orientation, inspection and serialization.

The synchronization and performance of the IP65 servos work equally well for high inertia turret drives and case packer conveyors as they do for delicate dual-component filling/container turning, torque-sensitive capping heads, and preprogrammed bottle plate motions for recipe-driven labeling of different container geometries

This class of distributed drive technology can extend upstream and downstream of packaging into the converting, manufacturing and warehousing processes.

B&R Industrial Automation, Inc.

www.br-automation.com

::Design World::

Filed Under: Factory automation, AUTOMATION, Slip rings + rotary unions, Packaging, ELECTRONICS • ELECTRICAL, Motors (direct-drive) + frameless motors, Motors • servo

Tell Us What You Think!