The solar industry has unique requirements for handling PV panels. Wafer-based solar module manufacturing processes are extremely sensitive, demanding smooth vibration-free, clean and efficient transport. The Glide-Line transfer system handles the high volume production needs of these projects.

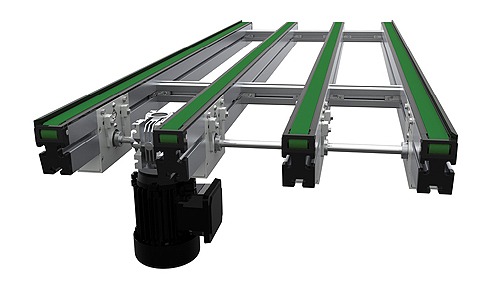

“Stress can cause almost invisible micro cracks in photovoltaic modules which, once installed, lead to a loss of power,” said Kevin Mauger, Glide-Line’s President. “We test every system to ensure low friction as well as ensure compatibility for ISO and ESD environments.” The Multi-Strand Pallet Handling Conveyor System is the foundation of the Glide-Line System. The conveyor transports PV panels through the assembly process. Transport conveyors offer multiple connection alternatives to suit a variety of assembly system requirements and are available with multiple power-input options as well, including 24 VDC motors. Sizes of the systems range from a minimum width of 140 mm to as many tracks as required.

Features include an optional centerline adjustable conveyor, configurable models for SolidWorks use, T5 timing belts with steel tension members for positive drive, durability and reduced maintenance, drive shaft 14 mm, end roller 28 mm, drive pulley 5 mm pitch, 40 tooth, B14 flange motor – 218 ft / minute.

A 24 VDC direct drive option for ultra-quiet maintenance free operation is also an option. It operates in absence of gearbox and connecting shafts. All rolling elements are precision ball bearing supported for long quiet, high-load operation.

Multiple, mounting drive configurations available AC single, 3 phase options, as well as 24 VDC options.

Glide-Line, a subsidiary of NCC Automated Systems

www.glide-line.com

Filed Under: Conveyors, MOTION CONTROL, Motors • dc, Motors (gearmotors)

Tell Us What You Think!