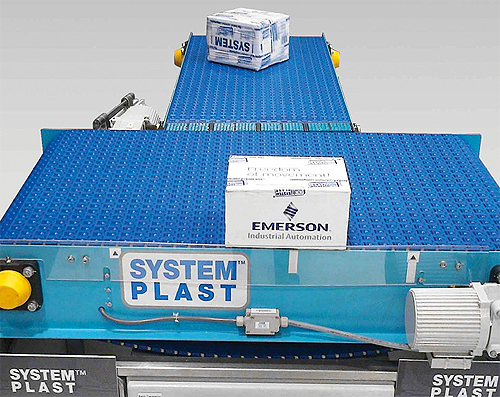

The System Plast multi-directional, roller-top conveyor belt makes packages dance to the user’s tune with the ability to align them to any angle, divert them, sort to multiple lanes, rotate, combine, or gap them – all non-contact. System Plast 2253RT roller-top belt simplifies conveyor system design and installation with its independently controlled moving surface with its multi-function product handling in a small footprint.

The System Plast multi-directional, roller-top conveyor belt makes packages dance to the user’s tune with the ability to align them to any angle, divert them, sort to multiple lanes, rotate, combine, or gap them – all non-contact. System Plast 2253RT roller-top belt simplifies conveyor system design and installation with its independently controlled moving surface with its multi-function product handling in a small footprint.

The roller-top surface easily handles large or small, flat-bottom products, moving them on 12.5-mm balls spaced on 25.4-mm (1 in.) centers. It supports loads up to 9,000 Nm/m (617 lb/ft) or 0.5 kg/ball (1.1 lb/ball). The belt’s non-contact product manipulation eliminates impact and abrasion damage from pushers, as well as the need for mechanical adjustment or changeovers for conventional diverters or guides.

The low-friction, 8.7-mm (0.34 in.) thick, acetal main belt is comprised of small cells carrying high-wear, free moving polyamide balls. Secondary drive belts underneath the plastic belt control the speed and rotation of the balls to manipulate packages while the belt is moving or stopped.

System Plast also conserves energy through its low-friction NG chain and Nolu-S wear track with a side-by-side demonstration comparing the electrical demand for two identical conveyor sections, one of them using industry standard LF acetal chain and UHMW wear track. For dry conveying applications in food/beverage processing, Nolu-S wear track with impregnated dry lubrication drastically reduces a conveyor’s coefficient of friction, eliminating the need for conventional soap/water sprays or any lubricant.

Emerson

www.emerson.com

Filed Under: Conveyors, MOTION CONTROL

Tell Us What You Think!