Belgium-based Nanocyl S. A. manufactures carbon nanotubes ranging in size from thin-walled to double walled and multi-walled versions. The company installed a Spirofil bulk bag filler to fill 45-lb and 100-lb bags with its products. To meet Nanocyl’s weight accuracy requirement of +/-0.7-oz (+/-20-g), Spiroflow engineers adopted a “hang-weight” principle. This meant that the highly sensitive load cells were mounted high in the filling area out of harm’s way. The product weighs the contents of the bulk bags. It is said that accuracy is particularly important when handling high value products such as nanotubes.

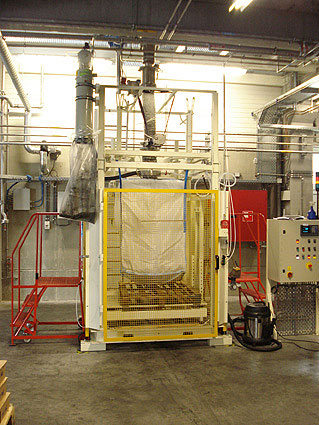

The Spirofil “Fill-by-Weight” bulk bag filler at Nanocyl has a safety cage open for rigging.

Bulk bag filling at Nanocyl takes place under a nitrogen blanket. A folded, flat bag is rigged onto the bulk bag filler and the bag is inflated with nitrogen. Given that the ambient air around the filler is 78% nitrogen by volume, the nitrogen is displaced as the bag is filled. The gas is vented through a special filter into the atmosphere.

During the filling process, the base of the bulk bag filler intermittently rises to vibrate the bag. The bag then lowers to allow weighing to continue. The bag is given a final vibration once the target weight is reached and recorded. This vibration is critical to ensure that the contents of each bag are stable and in safe condition for handling and storage.

The controls were designed and manufactured by Spiroflow. The heart of the control box is a high-accuracy weighing instrument that receives signals from the load cells. They support the bag hanging frame with quick release bag loop hooks. The weighing instrument is connected to a printer. The bulk bag filler at Nanocyl has been in operation for more than one year.

Nanocyl

www.nanocyl.com

Spiroflow

www.spiroflow.com

::Design World::

Filed Under: Factory automation, AUTOMATION, Packaging

Tell Us What You Think!