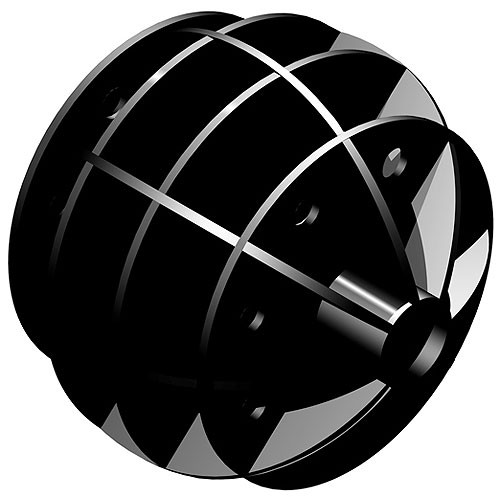

Baytubes® multi-wall carbon nanotubes (CNTs) will be used in an innovative safety technology design that should significantly reduce the risk of explosions in fuel tanks. Hirtenberger PROSAFE Safety Technology GmbH (HPST) is to use the nanotubes in the manufacture of newly developed spheres designed to prevent the formation of explosive gas mixtures in fuel tanks. The spheres will soon be introduced onto the global market under the name SAFEBALL. According to the manufacturer, they offer several advantages over the extruded metal mesh or plastic foams previously used for this purpose.

Once the spheres are placed into a tank, they completely fill it; yet only reduce the available volume of the tank by about 8.5%. The spheres not only prevent an explosive mixture of gas and air in a tank from exploding, they also allow the tank to “breathe,” so that significantly smaller quantities of hydrocarbons are released into the environment. Thus, the spheres could also contribute to environmental protection in the future.

Their special shape allows fuel to flow freely but prevents any dangerous surging. Surging occurs when large volumes of liquid are displaced, for example while a road tanker is in operation, thus affecting the vehicle’s stability. When a tank is to be cleaned, the spheres can easily be removed and then replaced once the operation is complete. They are also treated with anti-fungal and anti-bacterial agents.

All these benefits are due to the properties of Baytubes CNTs. Nanotubes exhibit a high level of electrical conductivity and mechanical strength and are extremely light in weight. “Without CNTs it would have been impossible to develop our technology so quickly,” said HPST CEO Thomas Stelzl, the inventor of the SAFEBALL concept.

Thanks to the development of an innovative, in-house production process, Bayer MaterialScience AG is one of the few companies in the world capable of producing CNTs of the required purity on an industrial scale. As early as 2007, the company started operations at a pilot plant in Laufenburg, Germany, that can produce 60 metric tons per year.

SAFEBALLS can be produced with a range of additional functions for special applications. These include fire extinguishing – for which a special gel is incorporated into the spheres – and the integration of active and passive transponders that enable vehicle data to be electronically stored to prevent theft or provide information on maintenance.

Bayer MaterialScience LLC

www.bayermaterialsciencenafta.com

::Design World::

Filed Under: Aerospace + defense, Materials • advanced, INDUSTRIAL SAFETY SYSTEMS

Tell Us What You Think!