MINNEAPOLIS, MN – NatureWorks LLC has achieved a manufacturing breakthrough with its Ingeo™ plastics made from plants, not oil. A new, proprietary manufacturing process commissioned late last year lowers CO2 emissions by 60 percent and reduces by 30 percent the energy required to produce Ingeo™ plastics compared to previous Ingeo™ production.

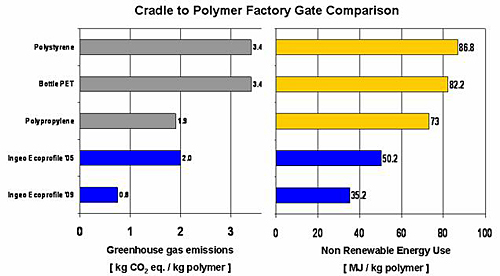

The emissions and energy reductions are even greater when Ingeo™ bioresin is compared to petroleum-based plastics. For example, the process of manufacturing PET (polyethylene terephthalate), the polymer most commonly used to make water and soda bottles and the mainstay of the synthetic fibers industry, emits 3.4 kilograms of CO2 per kilogram of resin produced. By contrast, the new Ingeo™ manufacturing process emits 77 percent less, with 0.75 kilograms of CO2 per kilogram of resin. The new Ingeo™ production technology also consumes 56 percent less energy than the equivalent weight of PET.

The improvement is not only over PET. Through this advanced production process, Ingeo™ environmentally outperforms all of the most commonly used petroleum-based plastics, including recycled PET. In determining the eco-profile for the new Ingeo™ technology, NatureWorks measured every significant input and output from seed planting to plastic resin being shipped through the factory’s gate.

The breakthrough in the eco-profile follows a decade-long collaborative research and development effort exploring advanced lactic acid production technologies. Research organizations included NatureWorks’ parent, Cargill, a network of biotechnology firms, universities, and government research laboratories. The effort was supported in part by grants from the U.S. Department of Energy, totaling about $25 million.

www.natureworksllc.com

::Design World::

Filed Under: Green engineering • renewable energy • sustainability, Materials • advanced

Tell Us What You Think!