(VENTURA, CALIFORNIA) — ThinGap Corporation has announced a NEMA 23 size Centrifugal Fan/Blower Motor that produces 30% higher shaft output than comparably sized fan and blower motors. The motor is ideally suited for fans and blowers in such space-limited applications as semiconductor processing and handling equipment, cleanroom vacuum and pressure fans, and telecommunications cooling.

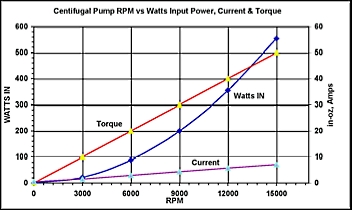

Centrifugal Pump RPM vs. Watts Input Power, Current and Torque.

“ThinGap's new centrifugal fan/blower motor provides an excellent solution for applications that have space limitations yet require high RPM,” said Rean Pretorius, CEO, ThinGap Corporation. “These high efficiency motors are continuing to push the envelope for packing higher torque, horsepower and RPM's into a smaller package and reducing energy consumption, all vital characteristics of the motors of the future.”

The ThinGap® centrifugal fan/blower motor is capable of delivering up to 1,025 watts shaft power (1.37 hp), 85 oz-in continuous torque at 16,300 rpm, while operating at 80 volts and 17.65 amps, including amplifier losses, yet the motor weighs only 16.5 oz.

The centrifugal fan/blower motor is based on patented electromotive coil technologies. By replacing the iron core and wire windings of conventional motors with a precision machined copper sheet, issues such as hysteresis, cogging and iron losses have been eliminated, and the impact of eddy currents substantially reduced. The design increases copper density, creating very high power-to-weight ratios, a wider range of speed and torque capability, improved heat dissipation, and lower electrical resistance.

www.ThinGap.com

:: Design World ::

Graph:

Centrifugal Pump RPM vs. Watts Input Power, Current and Torque.

Filed Under: Motors • dc

Tell Us What You Think!