Gates Corporation offers a new white paper, “How Belt Drives Impact Overhung Load.” The educational piece explains what overhung load (OHL) is, how it is calculated and the negative impact it has on shafts and bearings. The white paper also provides designers with solutions for reducing OHL and increasing belt drive efficiency and service life.

The white paper, which can be downloaded for free from Gates Ridiculously Powerful Belts page, defines OHL as “a force exerted perpendicular to a shaft beyond the outermost bearing.” When belt drives exceed maximum OHL ratings, shafts and bearings wear out faster than normal, prompting costly downtime for replacement and maintenance.

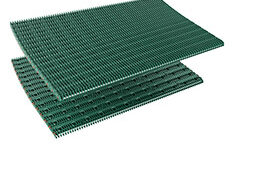

According to the white paper, if a belt drive produces an OHL level above recommended limits, the drive needs to be re-designed using narrower belts and larger diameter sprockets mounted as close as possible to the outermost bearing on the shaft. Gates Poly Chain® GT® Carbon™ synchronous belt drives can generate low overhung loads due to their very narrow widths.

The benefits of using a narrow belt with large diameter sprockets to reduce OHL include:

• Longer belt life; increasing sprocket diameter by 10 percent can double belt life

• Reduced bearing and shaft replacements

• Less downtime for maintenance and replacement

One company, a coal fired power plant, replaced belts and bearings on its pulverizer fan three times a year. Each replacement caused an average of eight hours of downtime and required two full-time maintenance workers. Converting the fan’s 10-strand V-belt drive to a narrower 4-strand Gates Predator® V-belt drive with a longer belt service life saved the plant $3,416 in component costs the first year and reduced maintenance costs by $1,809 annually.

To download the free white paper, visit www.gates.com/overhung. Or visit www.gates.com/casestudies to learn how companies have cut costs by reducing overhung load.

Gates Corporation

www.gates.com

Filed Under: Belts + chains

Tell Us What You Think!