Chain manufacturer iwis drive systems has developed a new monitoring system for measuring chain elongation. The new, patented CCM (Chain Condition Monitoring) system measures the wear elongation of chains in use and warns the maintenance personnel in advance if the chain needs to be replaced.

The CCM system can be quickly and easily integrated in numerous chain applications and retrofitted in existing plants and machines without the need for special add-on components for the chain. The device determines the wear in a chain drive and notifies maintenance personnel where and when preventive maintenance is required. Operating state and wear status are indicated by LEDs and readings can be transmitted to a computer through USB and viewed with a special interface. Because measurement is contactless, the chain drive is not affected in any way: no additional deflection pulleys or supports are needed.

“The main benefit of the new CCM system for our customers is that maintenance personnel can react on time”, explains Florian Madlener, design and development engineer at iwis’ headquarters in Munich, Germany, and a key developer of the system. “No long downtimes of plants and machinery, no risk of missing delivery deadlines, no interruption of the logistics chain: all of these contribute to avoiding financial loss through production outages. The system can also continually monitor high-precision chain applications.

The CCM system can be used independently of chain speed. Depending on the chain size, possible chain speeds range from 0.02 m/s to over 15 m/s. The device has protection class IP67 and can be used under normal environmental conditions and at temperatures from 0 to 60 °C. Calibration of the CCM system to the respective chain sizes is performed by iwis before delivery.

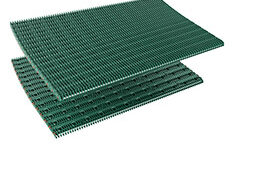

iwis supplies a comprehensive product range for all drives and conveying applications. The full programme comprises precision and high-performance roller chains, conveyor chains, maintenance-free and corrosion-resistant chains, accumulation chains, special-purpose conveyor chains, leaf chains, flat-top chains and modular belts for industrial applications, chains and accessories for agricultural machinery, and timing drives for the automotive industry.

Filed Under: Belts + chains

I need conveyor chain condition monitoring device for assembly lines & paint line