By Rafal Kasikowski, Design Engineer/Power Specialist, TT Electronics

Power efficiency is key to lessening global impact to the environment

Due to the intensifying impact humans are inflicting on the environment, it is important that our devices work to counter these adverse effects resulting from daily life and business as usual. External power supplies (EPSs) provide a unique opportunity to positively influence this effort. Contained and operating outside the devices they power, EPSs play a substantial role in total global electricity consumption. Resolving power conversion inefficiencies, however, can add tangible environmental value across the globe, for example, slashing energy consumption and lowering CO2 emissions. Competitive value follows as well, with EPS designers authorized to redirect recovered kilowatts into different applications. Newer, more eco-friendly systems enable product differentiation, ultimately boosting market share. EPS designers must support the regulations and energy conservation initiatives at play and plan for continued advancement of ecological concerns worldwide.

Grasping new and developing standards

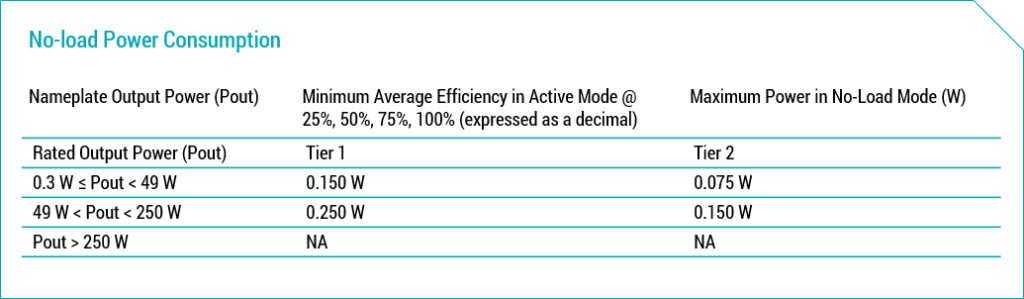

Many new, often parallel, regulations are advancing energy conservation in EPS design, formally acknowledging the relationship between today’s lifestyles and electrically powered devices. Overall, the goal is to certify EPS features with a high average energy efficiency and minimum no-load power consumption. Level VI standards, regulations developed by the U.S. Department of Energy (DOE), were instituted in 2016. The European Union (EU) followed with its Tier 1 and Tier 2 Code of Conduct (CoC) standards, created by the European Commission Joint Research Centre; while these standards are currently voluntary, it is anticipated they will become binding in the future.

Lowering energy consumption via Level VI standards

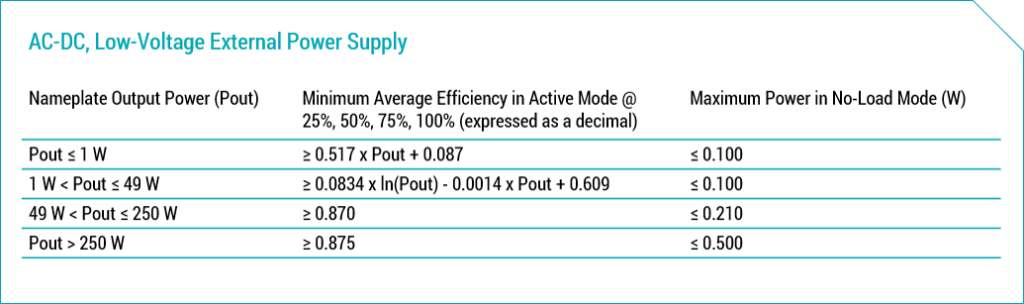

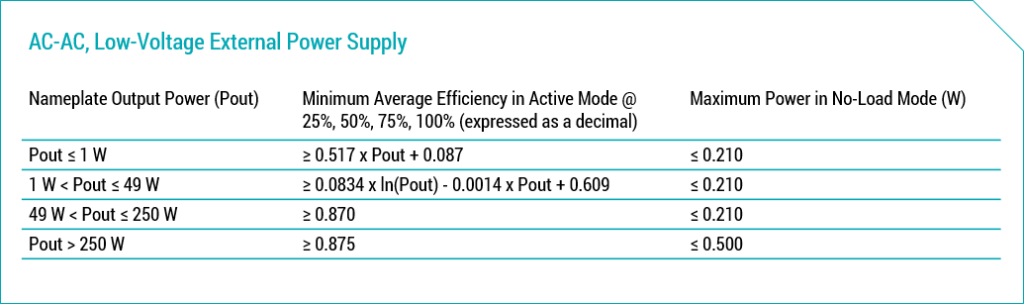

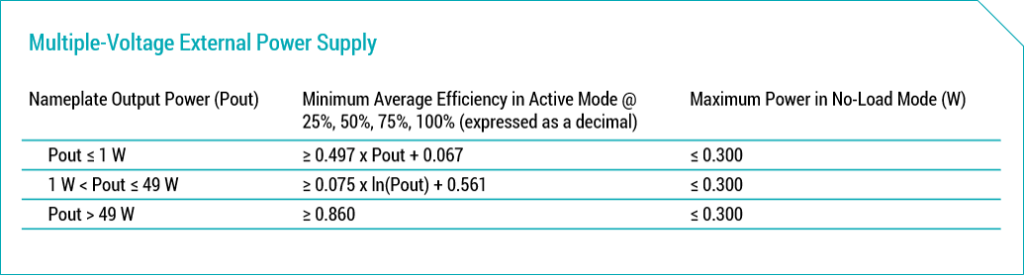

Two key performance criteria are outlined by the DOE’s Level VI regulations: no-load power consumption and minimum average efficiency limits in active mode. Measured at 25%, 50%, 75% and full load, these span a broad range of products including:

• Single-voltage external ac-dc power supply, basic-voltage (output voltage ≥6 V)

• Single-voltage external ac-dc power supply, low-voltage (output voltage below 6 V)

• Single-voltage external ac-dc power supply, basic-voltage (output voltage ≥6 V)

• Single-voltage external ac-dc power supply, low-voltage (output voltage below 6 V)

• Multiple-voltage external power supply

Table 1 presents minimum average efficiency thresholds and the maximum standby power EPSs in the above classes.

More stringent than previous regulations, the DOE’s Level VI legislation incorporates an entirely new category of multiple-voltage EPS options as well as a new 250 W output power level threshold. Table 1 describes a multiple-voltage EPS as ‘an external power supply designed to convert line voltage ac input into more than one simultaneous lower voltage output,’ while the ln(Pout) designation refers to the natural logarithm of an output power.

The DOE ruling also differentiates between direct and indirect operation EPSs. For example, direct options consist of external power supplies capable of operating a consumer product that is not a battery charger, without the assistance of a battery. The majority of EPSs in the direct operation category must comply with the parameters illustrated in Table 1. The new standards (Level VI) apply to direct operation EPSs only, but not all have to be compliant as the standards state some exceptions.

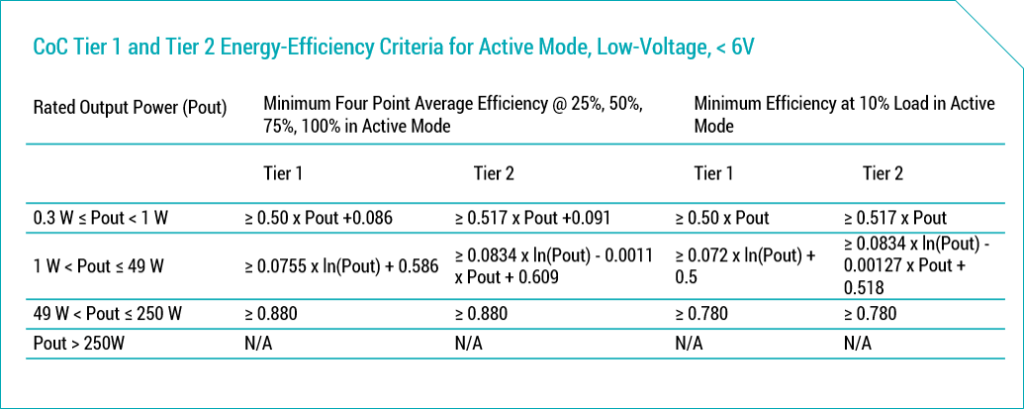

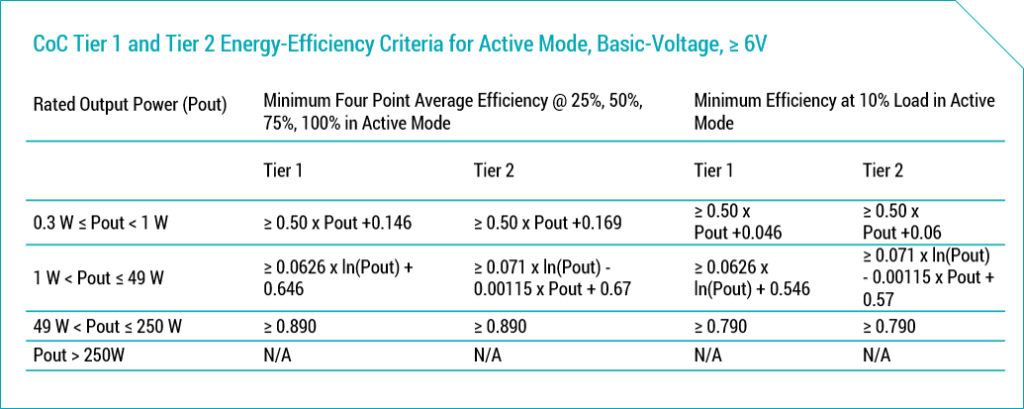

CoC Tier 1 and Tier 2 Energy Efficiency Criteria for Active Mode and Basic-Voltage.

An indirect operation EPS may not power a consumer product (other than a battery charger) without the assistance of a battery. For example, when an end-use product only functions while drawing power from a battery, the EPS associated with that product is classified as an indirect operation EPS. DOE designed this method to differentiate between direct and indirect operation EPSs, which requires manufacturers to determine whether an EPS can operate its end-use product once the associated battery has been fully discharged.

Understanding the changing EU Code of Conduct (CoC)

Like the DOE, the EU recommends minimization of EPS energy consumption in both no-load and load circumstances. Currently under revision and pending formal legislative approval, the EU has defined two distinct sets of provisions, known as Tier 1 and Tier 2. Tier 1 most closely resembles the DOE’s Level VI rulings, with some important differences such as implementation of a new 10% measure and a four-point average efficiency in active mode. There is no distinction between direct and indirect EPSs, and high-power EPSs (Pout > 250 W) are not subject to the regulations. Tier 2’s CoC is more sweeping and stringent, increasing performance requirements above the DOE’s Level VI standards as well as the EU’s Tier 1 for both no-load power consumption and the minimum average.

Planning for the future of EPS design

A smart, proactive methodology implements up-to-the-minute technologies and topologies with inherently higher efficiencies and low standby power features. However, tackling these new standby and efficiency requirements must not hinder EPS performance quality. Technologies must be selected carefully, weighing all performance parameters for any specific applications. For example, switching regulators outfitted with frequency-reducing features to boost light-load efficiencies may worsen output voltage – these are the types of parameters that can initiate unexpected end-user impact, or even render the product incompatible for certain applications if the burst mode is within audible frequency range.

Just as the DOE’s Level VI specifications became required, the EU’s Tier 1 and Tier 2 proposals will soon be formalized. Power supply design engineers and manufacturers must prepare for inevitable changes required to meet key performance criteria. In addition, compliance with these types of standards is likely to be an increasing challenge, as environmental concerns continue to take a front seat in legislation worldwide.

In the design realm, environmental responsibilities will only rise, affording engineers and manufacturers a unique opportunity in an evolving market. Compliant products will lower costs and empower new applications with recovered kilowatts. And shrinking energy consumption and CO2 emissions presents a highly competitive way to differentiate products, performance and market leadership.

TT Electronics

www.ttelectronics.com

Filed Under: Power supplies